Sowing the seed for generations

Granting of a water consent was the stimulus a couple needed to transform a Mid Canterbury sheep farm into diverse business. Story and photos by Annabelle Latz.

Granting of a water consent was the stimulus a couple needed to transform a Mid Canterbury sheep farm into diverse business. Story and photos by Annabelle Latz.

When the opportunity came up a decade ago to return to his family’s sheep farm and intensify the system, Darryl Oldham jumped at it.

The dryland 200ha in Westerfield had farmed 1300 crossbred ewes with some mixed cropping for two generations. When the consent came through 10 years ago to irrigate, Darryl (45) and his wife Anna (42) decided to move from nearby Ashburton and see how they could optimise the land.

Adapting to allow for irrigation included ripping out a lot of internal fences and changing lane ways to make way for pivot irrigation.

Five years ago the Oldhams decided to invest in Variable Rate Irrigation (VRI) because of the different soil types across the farm.

Darryl says they went with the Trimble VRI system. After five years of breakdowns and persistent problems, Trimble walked away from the system which was very stressful.

He says they are very grateful for the Carrfields team who helped them through getting the Lindsay Precision VRI back on their pivot.

The Oldhams use one T-L 360 centre pivot with Precision VRI installed and one T-L wiper centre pivot, drawing water from two deep wells and are deepening a shallow well. Darryl’s parents Peter and Gael did grow some crops alongside their sheep farming operation, mostly malting barley and wheat but at times also grass seed, red clover, peas and brassica for seed.

Darryl says water means more reliability on crop yields, being able to strike what they put in and hopefully achieve desired quality and yield.

“Without irrigation the farm could not support the two families.”

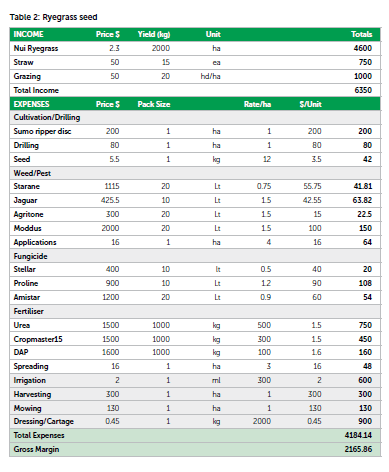

The 2023 harvest will be about 50ha wheat, 50ha grass seed, 30ha maize silage, 23ha peas and leasing 20ha to a potato grower. The rest of the area is dryland barley or pasture. The rotation revolves around getting fodder crops established post harvest for finishing lambs during the winter, mostly by direct drilling. Nothing is left to fallow anymore. They’ve tried different grass seeds but have mostly nui, the most widely planted perennial rye grass which offers a good steady yield and price at the moment.

“There is the ability to change grass seed varieties, although a two-harvest hiatus is required for variety change for certification.”

With any arable venture, the desire to improve tonnage is always there. They’re happy with the way things are looking for the season, although if the wet continues some areas may begin to suffer.

They’re trying to minimise inputs due to the tricky financial climate.

Their maize comes in at between 18-23.5 tonnes/ ha drymatter (DM), the feed wheat about 12t/ha, dressed peas sit between 3.5t and 4t/ha. The grass seed is variety dependent and anything from 1500kg – 2.5t/ha.

Owners of six combines

Onfarm machinery includes a Case IH 2388, two John Deere 9500s, three New Holland combines (they run a clover harvesting business), two Case IH tractors, a Great Plains air seeder drill, a Vaderstad Carrier and a 24 metre boom sprayer. They also have range of other machinery and implements on the farm including a mix of what his parents used which still operate well thanks to the dab hand of Peter in the farm workshop.

A local contractor does all their fertiliser spreading, utilising modern equipment and the ability to provide proof of placement through Tracmap and Hawkeye. The machines also have variable rate capability, which the Oldham’s have played with a bit and would like to use more in the future.

Darryl has also tried using liquid urea on some crops through their sprayer with good success and hopefully increase the area it is used on this season.

Weed challenges are fairly standard, with speedwell, thistles and dock being the biggest culprits although for certified crops the docks and thistle numbers are kept at bay.

“With our rotation we are using different chemicals all the time, so we’re hopefully keeping on top of resistance.”

They will sit with status quo for now, regarding inputs and any capital expenditure, as it’s even a challenge to work out budgets.

“Darryl seems to spend a lot of his time doing farm budgets at the moment,” Anna said.

Recently they’ve been busy with deep soil nitrogen testing, they also do leaf testing during the year, and only put on fertiliser when it’s needed.

“We’re not doing any capital fertilising at the moment or any improvements, we’re just sticking to maintenance.”

Since coming home they have invested in improving soil health and fertility, including working on building up soil humates.

The farm is basically split into thirds with soil types, including Mayfield silt loam, Wakanui silt loam, and a Rangitata stony loam down by the Ashburton River which borders the farm.

Chemicals are used as required and although they’re watching their pennies, cutting rates is something they want to avoid and has been possible with farm budgeting. Sticking within budgets and achieving targets has been possible by making sound decisions, largely through the help of local farm advisor Hayden Robinson of Lauriston Farm Improvement Club (LFIC). He came on board with the family after the 2021 floods which caused some feed budgeting issues and damage to some paddocks and cereal crops.

They were glad of Hayden’s input post flood.

“…once the water receded, we felt rather overwhelmed with the outlook.”

He comes out every six weeks or so, they go over everything. Darryl says it takes out some of the guesswork.

“It’s someone to bounce ideas off who sums up if he thinks you’re doing it right or wrong.”

Minimal soil disturbance

Although July has delivered record rain levels, getting seed into the ground should still be on track for this summer’s harvest. Using direct drilling, they’ll start with barley soon, peas in mid September, and maize mid-October.

They’ve been predominantly direct drilling for 25 years. Minimal soil turnover is their preference as protecting soil structure is the priority. They only get the discs out when required.

The Oldhams use a contractor for balage, straw and any cultivation they can’t do themselves, and he also buys the maize silage. They use Cates in Ashburton to sell their grain, and most of their grasses are contracted through G & R Seeds in Rakaia.

The Oldham family bought a local clover heading business two years ago, hence the number of combines. The idea is for this operation to fit in well with their own harvest, to kick in after the long hours at home are done.

This was not the case last year. There was a clash in timing and the weather was terrible from February onwards. The busy crossover was managed by Darryl sorting out the clover heading while Anna and Peter stayed on the home farm to manage their own harvest.

Darryl said it was frantic at times but their clients are marvellous and all seemed very understanding, considering the conditions.

“Hopefully it will be much more straightforward this coming harvest.”

For the past 11 summers, Anna has worked as a senior assessor for Asure Quality. She holds a Bachelor of Science in Agriculture and Food Studies she obtained back in England.

Sheep are still a feature for Paisley Farming Partnership, the name the family trades under. This year there are 2500 mostly crossbred lambs and some Halfbred store lambs on the farm. The aim is to increase the number of store lambs finished.

Until two years ago they wintered 600–1000 dairy cows, but the high number of regulations and consents required, and farming by the Ashburton River, put an end to this. Having no cows on the ground has also helped to reduce their N leaching figure through Overseer, while using soil moisture probes and VRI on one pivot also helped.

‘Consents are like tax’

Obtaining their land use consent to farm was relatively straightforward with the help of a consultant.

Darryl says the stress and headache caused by central Government’s rules of NES for freshwater, the potential SNA regulation continues, legislation like this takes away options and leaves no flexibility for farming systems.

“We can’t follow prices, or global trends, and it’s hard to move forward.”

Peter still spends most days of the week on the farm, but equally enjoys tinkering in his own workshop off the farm, admitting that the raft of paperwork and rules is a struggle to watch and he’s thankful they weren’t around to this extent when he was full time farming.

“Consents are like a tax, they add nothing to the farm, they’re expensive too, and take up time,” Peter said.

Darryl undertook a one-week farm manager’s programme through RaboBank last July, studying a range of topics that are all relevant to anyone running a farm business – financial management, growing business, managing people including yourself, communication and farm succession to name a few.

Part of the course was putting together a case study for a farming operation, and Darryl chose sheep milking.

It’s a venture they are seriously considering for Westerfield and are watching with interest how the industry develops.

“When you grow crops, you have a whole year to wait until you can see the results. With sheep milking it’s everyday, and bad weather will only lower a yield for a day or two.”

They’ve budgeted for the sheds for lambing and milking facilities for 600 ewes, and will wait to see if the capacity for milk drying in the area increases.

“We’d use one third of the farm for sheep milking, and continue to crop two thirds, dropping a portion of the grass seed area out for the sheep.”

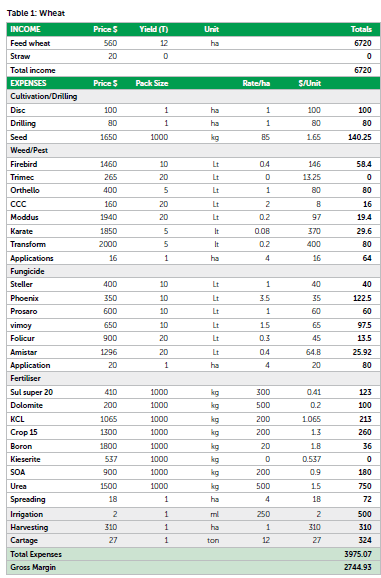

Darryl stresses the importance of having a very good grasp on knowing your costs of production, to avoid signing contracts where the farmer is coming off second best. In this current inflationary time costs have shot up so fast in all input areas.

One place Darryl and Anna have turned to for advice is Federated Farmers. The Herbage seed sub-section have been doing some excellent work on understanding the true cost of production, not just the gross margin.

“They have produced a spreadsheet calculator, which they are planning to make available to growers so they can assess the potential profitability of various ryegrass cultivars at any given price. This is going to be a very useful tool.”

Foundation for Arable Research is another organisation the Oldhams look to for advice. Its Production Wise Programme is an excellent tool for recording farm inputs and storing information when audited for on farm assurance schemes.

Darryl said it has not been all plain sailing, they have learnt the hard way on a few occasions, these tough lessons can really set them back both financially and confidence wise. They bought beef animals one year instead of grazing dairy cattle through the winter. When the price for feed went down to 20 cents/kg/DM, it did not work out in their favour financially. They’ve also had let downs with varietal choices in some of the crops resulting in disappointing yields.

Darryl and Anna have a bit of sound advice for young farming families like themselves, not get too hung up on the things that cannot be changed or are out of their control, like the weather. Striking a balance is important too, taking time to get involved in the community and taking opportunities to get off the farm. “We are working to achieve a whole life balance, trying to have a system in place that works without you having to be out there 24/7, life can be too short.”

They want flexibility of farm life, and the satisfaction from seeing a crop through its growth cycle to harvest time.

Being your own boss, being able to contribute to the local community and school, to help out with pea straw or head along to the rugby club and get to the children’s other sports, are all great things.

Success to the Oldhams is also about setting up a farm that is fit for future generations. Short term aims are to continue planting for extra shelter and for environmental improvements, medium to long term aims will be to increase the area being farmed with more cropping and more store lambs, or possibly milk sheep.

Hands on with crop

With a Bachelor of Science from Lincoln University majoring in farm management, Darryl spent time as a grain and seed agronomist for Cates Grain and Seed in Ashburton. He said moving back to the land was an exciting feeling, they’d done their figures and were looking forward to putting his knowledge into practice and exploring what crop farming offered now they had the ability to irrigate.

“It gets to the point where you’re telling other people how to do it, and you think it’d be nice to do it yourself,” Darryl said.

Anna is from the United Kingdom with a mixed farming background. Her family now live in New Zealand. Anna had been assisting her parents in Tinwald with their new venture, a commercial flower growing business, but was ready and willing to move into the family business venture with the Oldhams.

Darryl’s parents Peter and Gael are still involved in the running of the farm, now living in Ashburton, 20 kilometres away.

Life is busy, but changeable and interesting for the couple and their two daughters Henrietta (8) and Olivia (6) as they manage young family life, the nature of crop farming and potentials for the future.

It is important for Anna and Darryl their children grow up enjoying being with them on the farm.

They feel privileged to give the girls a rural childhood they both enjoyed.