Quality with every cut

Expanding their successful online Homegrown Farm Fresh Meats business to a bricks and mortar butchery and deli was a whirlwind for Wairarapa farmers Dion and Ali Kilmister. Story: Rebecca Greaves. Photos supplied by Homegrown.

Expanding their successful online Homegrown Farm Fresh Meats business to a bricks and mortar butchery and deli was a whirlwind for Wairarapa farmers Dion and Ali Kilmister. Story: Rebecca Greaves. Photos supplied by Homegrown.

The Homegrown Farm Fresh Meat ethos is know your farmer, know your food. Dion and Ali hand-pick every animal and have developed their own special meat breeds of lamb and beef to ensure the consistent quality of every cut.

Their attention to detail and delicious products were recently recognised with two gold and one silver medal at the Outstanding New Zealand Food Producers Awards, as well as walking away with the overall Supreme Champion title for their mixed box of gourmet beef and lamb.

Dion and Ali don’t do things by halves.

Country-Wide first featured the couple when they won the 2018 Wairarapa Sheep & Beef Farm Business of the Year. They had an inspiring pathway to farm ownership story and Dion showed remarkable resilience in the face of adversity. He lost his son Jayden and wife, Maria, in a short space of time, and they have been an important part of his story.

He met Ali, a self-confessed city slicker with a sharp business mind, at a pub in Wellington eight years ago and she became his partner in life, and in business. Together they have formed a formidable team.

A Homegrown butcher prepares a pair of legs of lamb.

Homegrown Farm Fresh Meats was in its infancy in 2018, having been launched as an online business the previous year, starting out with Farm Fresh Lamb boxes – half and whole lamb boxes, processed fresh to order.

At the heart of their story is the idea of encouraging customers to eat how a farmer would eat, utilising every cut of meat.

Fast forward three years and the Kilmisters have not been putting their feet up. Not long after the Farmer of the Year field day they took over and moved to their new property on the Pahiatua Track. They converted the dairy platform back to sheep and beef finishing, and it is from this farm that Dion selects the animals for the butchery.

Joe’s Meat Market in Masterton had been cutting up the meat for their online boxes, before Ali picked it up and packaged it for delivery to customers. When the opportunity arose to purchase Joe’s, it seemed a natural progression.

Based on customer demand, they took the plunge and bought Joe’s, taking on all the staff. They traded as Joe’s for six weeks before closing for a complete renovation, which took eight weeks. The Homegrown Butcher Deli and Pantry officially opened for business in September 2019.

Ali admits they never dreamed of having a shop, but they hadn’t reckoned on the demand.

“We even had local farmers asking about buying meat. It’s a bit of a dying art for shepherds, the butchery, and we’re looking at running classes for shepherds, to keep that education going. It (butchery) is a real skill and something I’m passionate about keeping going.”

Ali says Joe had done a great job at bringing on young guys and training them. As she puts it, they have taken them to finishing school.

They saw something in Jake Wiffin, 23 at the time, and quickly made him head butcher.

“Eventually, we hope he will be our succession plan. He’s passionate about what he does and how he does it, and he’s good with customers. Like us, for him the customer always comes first. He’s young, but he’s worldly mature.”

It was when they advertised for two qualified butchers, and couldn’t find any, that Ali realised what a problem it was. Instead, they put on two apprentice butchers and are training their own.

Waste is another challenge, but the Kilmisters are big on minimising waste and extracting maximum value. To that end, they have started making dog food, a dog roll for pets and Farm Dog Blocks for working dogs, which are portioned cubes of frozen meat.

They are even investigating providing a service to farmers, for those animals that are not able to go to the works, to turn them into dog tucker.

In the butchery and deli they created a hot food offering, building a commercial kitchen to serve lunch time food, which includes a lamb, beef or pork hot roast sandwich with all the trimmings, lamb, beef and smoked brisket pasties and sausage rolls. On Thursday and Friday you can get pork ribs. Ali says the offering is small, but it’s another way to ensure there’s as little waste meat as possible.

The butchery uses old fashioned methods. All sausages and small goods are made on-site and they have managed to get rid of 95% of plastic packaging. All meat is wrapped in traditional butcher’s paper, while some customers bring in their own reusable containers. Due to the nature of posting meat, they do vacuum pack all online orders, though they are in the process of changing to compostable vacuum packs.

Dion’s passion is for finishing animals. He loves to see a prime animal produced off his own farms, and prides himself on selecting animals for the butchery he himself would want to eat. He puts his hand on every animal personally.

They are gender specific, only using females to ensure consistency and eliminate testosterone spikes at different times of the year, and have their own breed of Charollais lamb and Angus Park beef (a cross using an Angus cow and a Speckle Park bull), which they have trademarked.

“The Angus Park gives an amazing eating experience, and that’s what it’s all about for us. We like to be different and we’re in a competitive market. Meat is meat, so you need something a little bit different to stand out from the crowd.”

The couple is the front of house crew every Saturday.

“I’m there Wednesday to Saturday and Dion is farming and in the shop on a Saturday. That’s special and gives him a buzz, to look at it and say ‘that’s our own meat’, we feel very privileged to be in that position.”

They put four to eight heifers and 20 to 60 lambs through the butchery a week, depending on the season and demand. Ali says there is a margin, but it’s not huge, and it’s not about the money.

When they started, lambs were worth about $90 at the farmgate, which created a better margin. With farmgate prices much higher now, the business is more of a passion project.

“Obviously it has to make money, but for the time and effort I put in, it’s definitely more of a passion project for me. We’ve always been about averages, even in our farm equation, riding out the highs and lows to get a good average.

“It’s about keeping as much of our good meat as we can in New Zealand, and that consistent product 12 months of the year.”

Operating in lockdown

After reopening as Homegrown Butcher Deli and Pantry it was a hectic five months before everyone’s world was turned upside down by Covid-19.

“It was summer, everyone likes a steak, it was a new business and everyone wanted to come in and have a look. We were so busy we still had our old website and hadn’t had a chance to update it.”

Three days out from the nationwide Level 4 lockdown they saw the writing on the wall. Ali’s son and his wife had just moved back from Melbourne. They spent two days and nights photographing every single cut of meat in the store and creating a new website.

“We were listening to what was being said and knew our shop frontage would be shut down, but we thought if we were online we could still trade. We moved very quickly to ensure we’d done everything necessary to continue online.”

Because they had already run as an online business, they had the logistics in place to make online ordering and delivery possible, albeit on a far larger scale than before.

For seven weeks they and their staff put in 16-hour days to get as much meat out the door as humanly possible every day. At one stage they ran out of ice packs and ended up freezing water in vacuum packs to make their own. Their front of house staff and kitchen worker became delivery drivers.

“It was daily problem solving. We had MPI in auditing things and it was a time of high anxiety for staff, and for us. For the most part, they were working their arses off and everyone else was at home with their kids on holiday, it was like Groundhog Day.

“We had this young business that could have gone belly up, but it thrived and we probably got access to more people, as people turned to online, and we had a far wider audience than normal. A lot of people have now gone back to what they knew, and convenience, but we have retained customers.”

Ali says they had to make decisions and act fast. “For right or for wrong, if you make a decision, you have something to work towards. If we had got closed down by MPI, we got closed down. But we made a decision to work towards something we thought was sustainable, and it worked.”

They didn’t take the wage subsidy and basically broke even for that period. Ali says it was exhausting, and they felt the weight of responsibility in being allowed to stay open. They came through the other end with a business and all their staff kept their jobs, which was the best case scenario. Ali says the experience did bring them all closer as a team, but it is one she hopes never to repeat again.

Winning the Supreme Award at the Outstanding Food Producers Award was the icing on the cake after a tough year.

“I felt absolutely elated. It’s one of those moments in time. What we do is hard work, if it was easy everyone would be doing it. The judges and chefs gave us amazing feedback, it was unbelievable really.”

Buying and selling

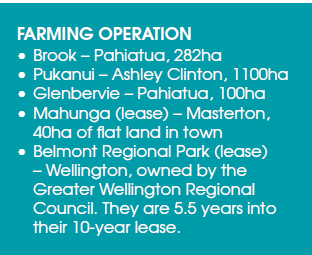

On the farming front, the Kilmisters have also been full steam ahead. Since buying the farm near Pahiatua in 2018 they elected not to renew several of their lease farms, hoping to give others the opportunity to get into farming.

Wanting to add more flat land near their home base, they recently made the tough decision to sell Canoga Park, at Bideford. Canoga Park was the farm where the dream began.

“It was Dion’s first lease back in 2005, the first opportunity ever. It was huge to let go of that farm – it’s where he lived with Maria and Jayden – all his history is there. But, again, that’s why it’s good to let go. It was his decision, but it has been hard.”

The couple had decided if the right property came up to buy, they would sell Canoga Park to their neighbour, who wanted it. When Pukanui, a sheep and beef station in Hawke’s Bay, came up for sale they knew the time was right.

“It’s in the Tukituki catchment, which is something new for us. It’s a whole new learning experience, what we can and can’t do.”

At the same time they also bought Glenbervie, a 100-hectare dairy farm, near their Pahiatua farm. The property is completely flat and the plan is to convert it to sheep and beef finishing too.

The contract manager concept discussed at their Farmer of the Year field day is still going strong, essentially giving the farm manager some skin in the game and rewarding hard work.

They know from their historical Cashmanager records the costs of running a farm, per year and per stock unit. The contractor is paid a yearly amount for running the farm in equal monthly portions, plus GST. This way the contractor has his own business within a business, taking care of things like budgeting and GST. They also build equity through ownership of plant and equipment.

Dion’s brother Kerry was their guinea pig, contract managing Belmont Regional Park and Ali says it has been a success. The model means Dion doesn’t have to sweat the small stuff. The contract manager employs the staff, monitors the day-to-day operations and takes care of things like how gear is being treated, which is important when he owns it.

Dion’s nephew Chris Kilmister was contract managing Canoga Park, and will move to Pukanui in the same role.

“One of Dion’s favourite sayings is ‘the sweat off your brow is your best reference’. There’s plenty of opportunity for them to pocket money, things like crutching, you can pay someone or you can do it yourself and keep that money.

“The biggest benefit is the opportunity for the contractor, the monetary thing is huge, but also for Dion and I, that small stuff doesn’t have to be sweated. It’s taken care of, and it’s taken care of by someone who has true buy-in. It’s really hard to find staff these days, we want to offer something different to get good staff and keep them.”

Trying something different sums up the Dion and Ali approach to life. They work hard, but they are passionate about that work, and they have a hell of a lot of fun along the way.