It takes technology and talent to finish 2,000 cattle

A South Taranaki property finishes thousands of prime cattle annually on challenging sandy soils with a great balance of technology and stockmanship. Words Tony Leggett, Photos Brad Hanson.

Finishing 2,000 prime cattle annually to 280–320kg carcase weight on challenging sandy soils on the South Taranaki coast takes bold management to succeed.

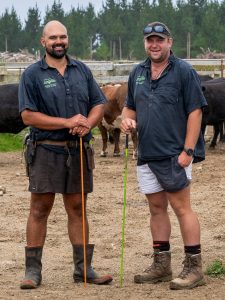

Longview Farm Manager Brandon Schrader has been in the driving seat for the past nine years, working closely with owner David Pearce to fine-tune their flexible, simple finishing system which captures the strengths of the station, but at the same time, mitigates many of its weaknesses.

Longview has an effective grazing area of 1,768ha of undulating sand country which rises gently from Waiinu Beach.

Coming up from the beach is a wide band of black sand soil and further inland, it turns to yellow-brown sands, then returns to black sands further inland.

Brandon says both soil types have shallow topsoil and limited organic matter, making them prone to drying out in a few days, especially with no rain and warm winds.

But two nearby finishing blocks and a 100ha irrigated block within the farm boundary, which takes wastewater from the adjacent Silver Fern Farms Waitōtara sheep plant, provide some guarantee of overall finishing capacity.

“Running a simple system means we can be very flexible, either offloading cattle or adding more if feed is building up.” – Brandon Schrader, Longview Farm Manager.

The finishing blocks are Karaka, 64ha of river flats 4km away in the Waitōtara Valley, managed by Brandon, and another 117ha just east from Waitōtara township on Highway 3 which is overseen by David.

Both blocks have their own yards and loading facilities, and it is always a one-way ticket for cattle going to either the fertile river silt flats at Karaka or the larger ‘D-block’ with its Egmont clay loam soils. Both finishing blocks also keep growing for longer than the main block when conditions turn dry, adding huge value to the overall operation.

“Some stock is finished on the main property, but more are grown out here and then pushed through to those blocks,” says Brandon. “I’d say 70–80% of the finishing of cattle happens at the two blocks, but it’s a goal of mine to do more finishing here on the main farm in the future. Having that 100ha of irrigated land is a real asset to the overall farm business too.”

Some balage and hay is made from surpluses on the station and fed to extend rotation length so they can get through short-term pinch periods. But cattle are grazed in large mobs, up to 500 head, and moved every 2–3 days almost entirely on pasture only.

“Grazing is pretty straightforward with small paddocks and big mobs. Rotation lengths vary throughout the year but can be on a 25- to 30-day round in the spring to 60- to 70-day round in the summer.”

Self-contained dairy beef

David’s experience with dairy cow management was an influence on the approach to beef finishing, with large mobs providing the same intensive rotational grazing approach used on the dairy farm. Longview has a long-standing grazing arrangement with two neighbouring dairy farms. Each winter about 700 dairy cows arrive for 6–7 weeks from 1 June to graze close to 170ha of pasture which is shut up on 1 April and primed up with a dressing of Sulphate of Ammonia.

About 400 come from the Pearce family’s own 308ha dairy unit adjacent to the station, and another 300 or so come from another neighbouring dairy farm, just opposite the nearby SFF Waitōtara sheep plant.

Between 20–25ha of land is sown in kale each year, specifically to feed 400 cattle for 60–70 days through the winter, to help with the pinch point between the dairy grazers and set stocking of the ewes ahead of lambing.An earlier beef system in place on the station was focused on producing local trade cattle, but they have stuck with mostly heifers finding they offer better flexibility than steers, and they are killable earlier to similar carcase weights if need be – a valuable asset when feed is disappearing over the summer months in the heat and flexibility is vital. Less than 30% of the station’s total stock units are sheep, so there is only a small natural increase each spring to help manage the surge in feed supply.

Unusually good growing conditions last winter through to December demonstrate the value of good monitoring and being ready to make decisions quickly, based on available feed. Brandon was able to buy in more cattle to take advantage of the extra pasture growth, but was ready to drop numbers when needed.

“It was quite helpful that we had a lot of forward cattle on farm after buying heavier store cattle (over 400kg liveweight) in late winter and early spring,” he says. “We had more stock ready to go when the pinch started to come on in December.

“In January, we sold close to 600 prime cattle and that is the key to farming this coastal country, just having that flexibility to do that. We could consider grazing stock elsewhere, but we tend to work with feed available, have it well set up to manage around, and know we can pull the trigger and drop numbers if necessary.”

When surplus feed is available, Brandon is also open to holding existing cattle on for longer to slaughter at heavier weights, provided they are not risking downgrading at slaughter for being too fat. Managing feed with that number of cattle on farm can be stressful, especially with growth very moisture-dependent.

“To make those decisions, it’s on a knife edge – one day we think we are right, then it changes,” Brandon says.

Technology plays a crucial role

Longview subscribes to the farm management software package AgriWebb which was developed in Australia and is now used in many other countries around the world. It is cloud-based and has a phone application which staff use to update stock movements along with other farm management information.

To shorten the regular farm ride, often done with Head Shepherd Jack Larsen, Brandon downloads the ‘days since last grazed’ report from AgriWebb and only goes to the paddocks grazed the longest time ago to gauge regrowth and assess overall feed supply.

“If our grazing round is 30–40 days for instance, I can go to all the paddocks grazed 30 days or more ago and see what’s happening. That gives us a good feel for what we’ve got in front of us, but does still take gut feel and a look at the weather forecast to factor all those things in as well.”

Both finishing blocks are also viewed each week to assess their potential.

Brandon also completes a full farm ride each month and updates the feed position in feed budgeting software package FARMAX, to formalise his feed position which helps to further support his buying and selling decisions.

“My aim is to update the FARMAX report at least once a month to get an actual feed available and to have a look ahead for the next 2–3 months to give an idea how it is looking. I run FARMAX at a basic level. It’s more of an overview of the farm, but the peace of mind and decision support is valuable.”

With up to 2,600 or more cattle on the station and its finishing blocks at any one time, it is not surprising that one of Brandon’s biggest challenges is sourcing sufficient numbers of store cattle. “In recent years, we’ve had to add a few steers into the mix to make up the numbers. The cattle are no specific breed or breeds because we buy in from all over the show.

“They are different ages and weights throughout the year; as we offload to slaughter we are pretty much buying back in to replace them, depending on feed surplus or deficit. We will buy most breeds you can think of, not so much the straight dairy breeds, but we have good results out of the dairy beef breeds, getting most of them up to 280–320kg on the hook.”

Keeping an up-to-date stock reconciliation is done using the Figured add-on to Xero accounting software. Brandon loads in the invoices and numbers, and David matches up the payments and reconciles the invoices.

“Predicting a surplus is as valuable as predicting a deficit because if feed does get away on us, it’s hard to get it back under control and performance can be compromised.” – Brandon Schrader, Longview Farm Manager.

“Modern online accounting systems like Figured & Xero are easy to update and visible to everyone,” David says. “It’s not like the old days when nobody knew what results were until six months after balance date.”

Brandon shares the workload with two full-time staff (head shepherd and fencer/general) and one casual staff member doing about 20 hours each week. David often provides cover for staff on the weekends and looks after the finishing block near his home.

With 226 paddocks, keeping track of mobs and movements is challenging without the use of technology and a big whiteboard with the farm map is set up in the workshop and updated before each daily morning meeting.

Small magnetic tags are created for each mob and these are moved as each mob shift is completed, meaning even the less tech-savvy staff members are up to speed and it is particularly helpful when staff are away and others are covering their roles.

Staff use AgriWebb’s mobile phone application to record movements and any farm activities, issues like broken rails or water problems, updates if a mob enters the yards for drafting out prime animals, or sorting into mobs of similar condition and weight, or any animal health issues or treatments.

Despite technology, growing cattle is still by eye

Despite technology, growing cattle is still by eye

Brandon and David will often attend nearby sales around the region to check on the market, but most cattle are bought through several local stock agents.

“Sourcing enough stock will be a challenge going forward,” Brandon says. “It’s tougher to find good straight-bred station cattle, those numbers are getting short, and there’s a lot more dairy-cross beef these days on offer. There is nothing wrong with them, but the quality of stock generally is falling away.”

Most cattle arrive in two main buying-in periods – August-September (and into October this year because they had surplus) and then in autumn when many cattle are sold prime and they need to be replaced to get numbers up to what they want to winter. When cattle arrive on the farm, they have a colour-coded management tag fitted along with a station ear mark and a pour-on anthelmintic. The management tag gives staff a visual signal of the age of the animal and avoids them being downgraded on age.

“We are shifting our big mobs of cattle quite regularly, so we are observing them for animal health issues a lot as they walk through the gates,” says Brandon. “They are in the yards often for drafting and sorting into sizes and classes as we offload the prime cattle, so we pick up on any crook cattle pretty quickly.”

“On some farms, it’s all on liveweight. We do all our fat drafting by eye in the yards ourselves for both our cattle and lambs so that we know we have grown our stock to their full potential and make sure they are ready to be slaughtered based on fat cover and condition.” – Brandon Schrader, Longview Farm Manager.

The scales and crush in the central cattle yards get limited use. Cattle that graze the kale over winter are weighed on and off the crop, but all prime cattle are selected by eye in the yards, with David involved 90% of the time.

“On some farms, it’s all on liveweight,” explains Brandon. “We do all our fat drafting by eye in the yards ourselves for both our cattle and lambs so that we know we have grown our stock to their

full potential and make sure they are ready to be slaughtered based on fat cover and condition.”

Kill sheets support their eye appraisal strategy, with high percentages of Longview cattle meeting the Silver Fern Farms’ Reserve Grade requirements for cattle slaughtered on winter contract.

Longview also won the best prime beef and overall award for Western North Island suppliers to Silver Fern Farms for 2024.

“You can check the NAIT tag and look up the origin of each animal on the NAIT website, but a visual tag with some background information would be really helpful for our situation,” he says.

David is keen to see cattle breeders and dairy beef suppliers put a management tag into their cattle that makes it easier for finishers to identify cattle they want to buy each year because they perform well in their system.

Key facts

Key facts

- Farm: Longview

- Farming: Beef finishing, lamb breeding-finishing

- Area: Total of 2,148ha (Main block: 1,768ha (effective), Karaka: 64ha, D-Block: 117ha, Forestry: 342ha)

- Infrastructure: Network of metalled laneways, central cattle and sheep yards

- Paddocks: 262

- Staff: Full-time manager, head shepherd and fencer-general, two part-timers

Fertiliser and fencing support Longview success

Longview was a clean slate when David Pearce bought the freehold title to the land in 1993.

The farm had never been homesteaded before Longview bought it, possibly because the tenure was only a ‘licence to occupy’ until the 1980s when it finally became freehold land.

Although it took longer and needed substantially more investment than expected to “knock it into shape”, David has consistently invested in land and infrastructure development, creating metalled laneways which all lead to centrally located cattle and sheep yards, building houses and subdividing it.

The annual fertiliser programme is developed in conjunction with a consultant from independent advisory firm AgKnowledge.

Regular soil testing is carried out to produce a detailed recommendation for two annual applications of fertiliser. More recently, clover samples have been taken twice a year to assess its level of Molybdenum, a key element supporting the clover plant to fix nitrogen in the soil.

David still looks after some development work and provides staff cover on the weekends, but is content to leave more of the day-to-day management of the property in the

hands of long-time Farm Manager Brandon Schrader.

Brandon arrived at Longview 16 years ago asking for a summer job so he could leave high school in Whanganui and start his career in farming.

He has been managing the property for the past nine years and has a share-farming arrangement with David based on a percentage of the gross profit after some running costs are deducted.

For the past four years, Brandon’s responsibilities have also included staff recruitment and remuneration so the two full-time and one part-time staff members work for him and he invoices Longview monthly for the total package as a contractor.