Good future in stores

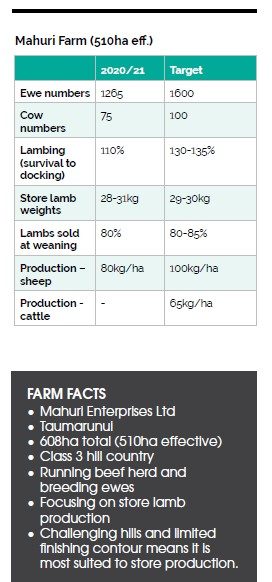

Challenging hills and limited finishing contour means Mahuri Farm, north of Taumarunui is most suited to store production. Story and photos by Mike Bland.

Challenging hills and limited finishing contour means Mahuri Farm, north of Taumarunui is most suited to store production. Story and photos by Mike Bland.

King Country farmers Nathan Blake and Libby Wood aim to breed ewes that are perfect for producing good store lambs on their new hill-country farm.

Recently engaged, the couple farms the 608-hectare (510ha effective) Mahuri Farm, just north of Taumarunui. They bought the farm this year and are in the process of breeding a Coopworth-Perendale flock that can handle the hills and deliver hardy, fast-growing lambs that are ideal for the store market.

Nathan was raised on a 900ha sheep and beef farm just up the road at Eight Mile Junction. His parents, Tom and Heather, and his uncle and aunty, Jim and Lindsay, bought Mahuri as part of a succession plan in 2014.

Nathan was on a working holiday in Wales at the time and had to rely on their good judgement as he had already committed to managing the farm when he got back.

“They sent over some photos and asked me what I thought.”

The senior Blakes have since sold the Eight Mile Junction farm and retired to Tauranga and Cooks Beach, but they still visit Mahuri on a regular basis. Nathan managed Mahuri for the first few years, then he and Libby bought the stock and leased the land for another three years. With help from family they were able to buy the farm in July.

Farm ownership had always been a goal for the couple. They also share an interest in livestock breeding. After graduating from Taratahi, Nathan spent almost three years on Wairere Romney Stud in Wairarapa before moving to Seven Hills Angus near Pahiatua for another two.

Working on top stud farms taught him a lot about sheep and cattle breeding and this knowledge has been put to good use on Mahuri.

Mahuri has about 20ha of flat to rolling contour and 490ha of medium to steep (Class 3 – North Island hard hill country), with the remainder mostly in native bush.

Its challenging hills and limited finishing contour means it is most suited to store production and the couple have considerable development work planned. Fencing and soil fertility are key priorities. Mahuri was split into 26 paddocks five years ago, and over the past three years Nathan and Libby have increased this to 36.

Nathan says the largest paddock still totals 120ha and takes several hours to muster.

“We stock it with about 75 steers in winter and forget about them.”

This paddock will eventually be subdivided but for the moment the focus is on improving most productive areas of the farm. Nathan and Libby are also fencing off waterways and native bush.

“One of the first things we did was draw up an environmental plan. We’ve also focused on lifting soil fertility,” Libby says.

Capital fertiliser has been applied to 250ha of the better-contoured and subdivided land. “Once we’ve got that block humming, we will extend that out to the rest of the farm.”

Stock on Mahuri initially consisted of trading cattle and a breeding flock of various breeds. Bordered by pine trees, the farm is also home to a large number of feral goats. These can be a major problem as they find holes in fences and consume a considerable amount of pasture.

Nathan musters goats whenever he can and sells them, but they keep reappearing. He and Libby hope numbers will reduce as the subdivision improves.

Sheep performance in the early years was underwhelming. Nathan says pleurisy and facial eczema were affecting ewe health, and lamb production was poor.

“So we decided to start from scratch to build a flock that would better suit this block and produce lambs that are healthy and well-grown at weaning.”

Getting the right mix

This year Mahuri is carrying about 1000 mixed-age ewes, 265 two-tooths and 270 hogget replacements. Next year about 1500 ewes will go to the ram, with the goal of reaching 1600.

The flock includes Romney, Perendale and Romdale ewes but Nathan and Libby are breeding towards the Perendale-Coopworth cross they feel will be a good match for the farm.

Since 2018, Perendale and Suffolk rams have been sourced from the Raupuha Stud, Mahoenui, and this season about half of the maternal-mated ewes went to Kirikau Coopworth rams from The Poplars Farm, Kirikau.

Libby says these studs are a natural fit for the business “because they are both breeding exactly the characteristics we want”.

The couple take sire selections seriously. They have to like the look of a ram, but the figures have equal weighting.

“Maternal EBV’s are very important. We are a store property so we want healthy and well-grown lambs at weaning. Survivability and FE tolerance are also crucial, and our aim is to breed sheep with a natural resilience to internal parasites.”

When ewe numbers reach the targeted 1600, about 600-700 will go to Perendale or Coopworth rams and the rest will go to a Suffolk or Beltex.

Nathan says the goal is to breed sheep that are free-moving and easy to muster on the hills. The ‘ideal’ ewe will weigh 65-70kg, have good mothering and milking ability and rear lambs to 30kg at weaning. They will scan at 170-175% and lamb at 130-135%.

“We don’t really want triplets because they are too hard to manage on this type of contour.”

Libby says the original ewe flock was not ideally suited to the farm, and FE and two drought seasons may have had a long-term effect on production. So she and Nathan are working towards improving ewe efficiency by culling out the older, poorer-performing ewes.

Condition scoring (CS) is a key tool and it’s something they are learning to master. Libby says she was lucky to be taught by good vets. Ewes are condition scored at key times, including scanning, pre-mating, weaning and docking.

“Ideally, we’d like to get ewes to a minimum CS of 3 at mating, so anything below that will get preferential treatment.”

They are always identifying the poor performers and focusing on them, not looking at averages.

“High CS ewes can look after themselves, the biggest payoff comes from adding half a CS to those lighter ewes.”

She says good genetics are a crucial part of the breeding programme.

Potential replacement lambs are tagged at docking using coloured year-tags, but if the lamb shows any undesirable traits, such as poor growth or parasite issues, the tags are removed and the lamb is sold after weaning. Poorer performing two-tooth and mixed-age ewes are also de-tagged and mated to a terminal sire.

“We want to get consistency in the ewes so they all have an equal chance of producing good lambs.”

Nathan says about 100 ewes will be culled this year, based on factors like condition score, lambing performance, udder and teeth.

The farm has a relatively low stocking rate as stock numbers are still building, and ewes are given plenty of space before lambing. They are set stocked from late July on 200ha at about 5.1 ewes/ha for the maternal-mated twinning ewes, and 5.2 ewes/ha for terminal-mated twinners. Single-bearing ewes are stocked at about 5.7ewes/ha.

Lambing starts on August 10, which is early in the region but suits Nathan’s off-farm casual work.

Libby says while the present lambing date is a good fit for the farm’s pasture growth curve, she and Nathan will use Farmax modelling to see if a change in date will make a difference to sheep performance.

Fertiliser is used strategically to boost feed supplies to meet ewe demand. This year about 30 tonnes of DAP were applied to lambing country at 150kg/ha in late July. Libby says this generated more feed for lambing while also boosting P levels.

“For every dollar we spend, we get back an extra $1.50 in higher lamb weights and better ewe weights at mating.”

The couple has learnt a lot from the last two drought years. Careful budgeting has been crucial, as has expert help from a good bank manager and a good accountant.

Libby says they now plan for a drought every year and are budgeting 3-5years ahead.

“It’s given us the confidence to pull more levers, and that includes selling cattle early, applying pre-lamb nitrogen and not being afraid to extend the overdraft if we have to. It’s more risky to do nothing.”

Nathan says wool is still considered when selecting rams, despite low prices.

A recent rise in wool prices has given the couple some confidence.

“It’s not profitable currently, but we believe it will come back.”

Store lambs drive profit

A lack of good finishing contour means Mahuri is best suited to store lamb production, and this generates over $100,000 in annual income, Nathan says.

In 2020/21 the farm sold 1150 lambs – 80% of which went store at 28-31kg LW between late November and early December. The remainder were finished at 16-18kg CW.

Nathan says terminal-mated ewes go to Suffolk or Beltex rams because their progeny are easy to identify and very marketable, earning a 10-20c/kg premium.

He says lamb weights improved this season due to better genetics and grass growth. Blackface lambs averaged an extra 2kg and the whiteface lambs were up 3kg. Previously, store lamb weights have ranged from 21 to 31kg, but the aim is to consistently get blackface lambs to 30kg and whiteface lambs to 29kg.

The ability to sell the bulk of the lamb crop at weaning is crucial to the system’s success. Only a small number of finishing lambs are carried through the summer and the aim is to have no lambs on the farm by March when the rams go out.

“We are a good store property and we don’t chase the market.”

Libby says the key to producing good store lambs is to focus on the ewes. This starts from the day their lambs are weaned. Getting lambs away early gives the ewes a head start for the next season.

Tail-end ewes are drafted at weaning and given preferential feeding to get weights up. Faecal egg levels are monitored carefully and ewes are drenched only if they need it. This, in combination with the selection of worm resistant sires, is part of a plan to reduce the risk of drench resistance. The couple also monitor for FE and Barber’s Pole worms.

Lambs are drenched before weaning, and at docking they get a Multine B12 shot and are vaccinated for scabby mouth.

Suck it and see

Even though 250 hoggets were mated for the first time this year, hogget mating is not considered a priority on Mahuri in the short term.

Nathan says the hoggets were mated because the farm had good pasture growth after two tough years and was understocked.

They went to Coopworth rams at a minimum of 40kg and were farmed on easier contour with plenty of shelter.

“We had the extra feed, so we thought why not give it a go and see what happens. They only scanned at 42% but if we get an extra 100 lambs out of it, that’s still a bonus.”

Its unlikely hoggets will be mated next year because Nathan and Libby are aiming to lift the stocking rate.

Libby says they will continue to focus on growing hoggets as much as possible.

“When we’ve got the mixed-age ewes performing at the level we want, that’s a good time to look again at hogget mating.”

Cow numbers rising

The farm still runs about 75 trade steers, and about 30 home-bred and reared weaner steers were sold in March at an average of 203kg. Non-replacement heifers are sold as weaners. About 30 heifer replacements were retained this year and Nathan says about 80 cows will be mated next season.

The herd includes a mix of Angus, Angus-cross, Hereford and Hereford-cross but the plan is to breed towards an all-Angus herd of about 100 cows.

When cow numbers reach this target and ewe numbers hit 1600, Nathan and Libby conservatively estimate the farm will generate an extra $40,000 in lamb and cattle sales.

This year they are also rearing 50 Friesian-Hereford and Friesian-Angus calves, which will be sold at 100kg.

Cows and trading steers are used to control pasture quality in late spring, but if feed gets tight the steers are sold to free up feed for the breeding ewes.

KEEPING IT SIMPLE

Nathan and Libby try to keep management of Mahuri as simple as possible so they can run it with minimal outside labour.

Family members and friends help out when they can.

Nathan met Libby five years ago. Raised in rural Lincolnshire, England, she moved to New Zealand with her family in 2007 and lived on lifestyle blocks in the Waikato and King Country while her father, Colin, worked as a teacher.

Libby reared calves or dairy goats with her mother, Alison, and loved working with horses. In 2009 she went to Massey University to study for a degree in agricultural science. Since graduating she has worked in a range of agribusiness roles, most recently as a nutrient specialist for Ballance AgriNutrients.

The job gives her flexibility, allowing her to work on the farm when needed.

Nathan also works off-farm on a casual basis, doing mustering and yard work.