Farm Environment Plans are an increasingly common requirement, especially for those irrigating, and good management practice (GMP) is required to pass FEP audits. Andrew Swallow reports from a workshop with Irrigation New Zealand’s national technical manager Steve Breneger on how to achieve GMP with irrigation.

All the gear; no idea!”

It’s a comment you’ll sometimes hear on a skifield, golf course or cycle track, but it can equally apply to irrigation, Irrigation New Zealand’s national technical manager Steve Breneger warns.

“A guy with VRI (Variable Rate Irrigation) and a centre pivot who doesn’t know how to use it is just as bad as a guy with an irrigation gun, in fact worse, if the guy with the gun knows how to use it,” he told a recent workshop at South Canterbury’s Opuha Water Limited (OWL).

The latest technology also must be installed and commissioned correctly for it to deliver improvements in efficiency promised in the sales pitches but a survey of more than 200 systems in Canterbury over the past three years found all too often that’s not been done. INZ has been on a mission since to see that suppliers follow-up sales with a commissioning service to ensure systems do what they’re supposed to do.

At the same time, it’s been running workshops around the country to bring irrigation operators up to speed with how to achieve good management practice with whatever system they run.

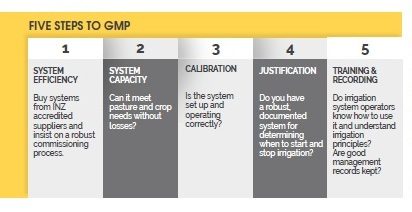

There are five core areas: system efficiency; system capacity; calibration; justification; training and recording.

SYSTEM EFFICIENCY

System efficiency can only be measured if a system has been designed to a performance standard, with the efficiency being how it performs relative to that standard. Checking performance with a formal commissioning process on installation is vital.

“If you’re spending half a million dollars on a pivot I’d want evidence it can do 5mm applications and all the other things you’ve bought into,” Breneger says.

An irrigation system is only brand new for one day in its life so it’s really important performance is checked prior to practical use, he adds.

Efficiency can only be quantified on older systems if a performance standard for their operation is available. Bucket tests should be done to check what’s actually being delivered. Do not rely on flow or pressure readings.

Breneger says there are standard test procedures for every type of system. See https://www.irrigationnz.co.nz/

PracticalResources/GMP/Overview

System efficiency is different to water use efficiency, the latter being how much of applied irrigation is used by the pasture or crop it is applied to. The national target is 80% or more and system capacity, the second of those five core GMP areas, will determine whether that’s achievable.

SYSTEM CAPACITY

A system’s capacity will determine the range of application depths it can deliver, at what uniformity, and what intensity. Capacity needs to be tuned to soil, topography and land use so infiltration rates and soil water capacity are not exceeded but crop demands are still met.

For example, on deep, finely textured soils, even flood irrigation can be highly efficient if well designed and managed, but if soil water holding capacity is limited, such as on a shallow or sandy soil, flood becomes highly inefficient.

Whether a system delivers on its capacity also depends on how well it’s managed and maintained. “Look at it every once in a while and ask yourself: is it working well?”

A frequent cause of poor performance on pivots and laterals is nozzles replaced with whatever was on the ute or quadbike at the time. The difference between a number 30 and 35 nozzle might not sound very much, but the flow-rate leaps from 32 litres/minute to 45L/minute respectively, he says.

Side-roll, drip, and micro irrigation systems are, by design, highly efficient and even K-line and guns can be managed to achieve 80% WUE, but the one system in common use that can be challenging to manage to that level is Rotorainer due to its “McDonald’s arches” distribution uniformity, Breneger says.

“The application intensity is terrible at the edges of the run.”

CALIBRATION (AND MAINTENANCE)

To achieve GMP, calibration and maintenance of an irrigation system is “not just checking oil and tyres.”

For pivots, speed calibrations are a common fault and need checking. Nozzle wear is another area to watch, especially after 10-12,000 hours use. Typically, in Canterbury, pivots run for about 2000 hours/year so expect to replace nozzles every five years, Breneger says.

As a rule of thumb, greater than 20% variation in output between a representative sample of nozzles taken from along the machine signals wear is reaching an unacceptable level.

Nozzle wear increases further along pivots as sediment gets carried to the ends and flow rates are higher, but Breneger recommends replacing nozzles as a set, rather than piecemeal, “otherwise it gets really messy” trying to keep track of what was done, and when.

Wear of the sprinkler regulators on pivots and laterals is driven by age rather than amount of use because corrosion continues whether the pivot is running or not.

JUSTIFICATION

The minimum justification for irrigation expected for GMP is a water balance sheet, taking account of soil available water capacity, rain, irrigation, and evapotranspiration. Ideally, some allowance for forecast rain should also be made.

“If forecasts are unreliable your policy might be to shut off when rain starts, or if the probability of the rain forecast is over 90%… It’s just proving that you’re putting some thought into your irrigation and not just going outside and saying ‘Yep, let’s go!’.”

Soil moisture sensors are good tools, but should not be relied on in isolation. Nor should signs such as grass going crinkly in the heat of the day. “Provided it comes back when it cools down that’s not necessarily a sign you need to irrigate.”

TRAINING AND RECORDING

Whatever the trigger is for a decision to irrigate, it needs to be recorded to achieve GMP, as does the reason to switch off. “You need a one-liner on why you made each decision.”

Other records expected are time, date, irrigation applied, rain (if any), and location.

Operators of irrigators should understand how to operate the systems they work with and any training undertaken to achieve that should be logged.

“If you can show you are doing all these things (1-5), then you’re achieving GMP,” Breneger concluded at the OWL workshop.

WORKSHOP ONE OF MANY

Breneger said he’s run about 30 workshops a year like the Opuha Water one for the past couple of years, with about 800 attendees/ year. About 20% are service industry personnel or consultants and the balance farm irrigator operators.

“There are about 13,000 irrigating farmers in New Zealand, 99% of which would be farm-scale,” he told Country-Wide.

About a million hectares of NZ could be irrigated and 805,000ha of that is now watered. Not much of the remainder will ever be irrigated, he believes.

“It’s the old 80:20 rule – the first 80% is easy and the last 20% is increasingly hard to do… It won’t matter if there’s a change of Government. What’s left to do comes with inherent problems.”