Fast finishers

An artificial breeding programme underpins impressive beef growth rates on an East Coast farm. By Sandra Taylor. Photos: Rebecca Williams.

WHEN MICHAEL AND MANDY Loffler’s bull calves tipped the scales at 400kg at weaning this year, it was a good indication they were on the right track with both their genetics and their feeding.

That these calves were from their yearling Angus Simmental cross heifers made these weights even more remarkable.

Some of the heifer calves from the yearling heifers weighed up to 370kg, while the smaller heifers and steers still weighed an impressive 311kg.

These weights meant the R2 heifers were weaning 57% of their body weight which augurs well for the efficiency of the couple’s mixed-cow herd.

Underpinning these impressive growth rates is an artificial breeding programme which, over the past 20 years, has significantly sped the genetic gain in the family’s commercial breeding cow herd.

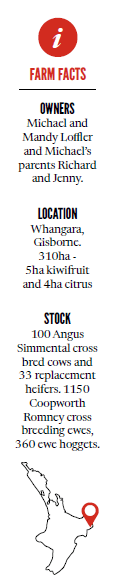

Michael, his wife Mandy and parents Richard and Jenny farm 310 hectares at Whangara in Gisborne, running 100 Angus Simmental cross breeding cows and 33 replacement heifers alongside 1150 Coopworth Romney cross breeding ewes, 360 ewe hoggets, a 5ha kiwifruit and 4ha citrus orchard.

The sheep-to-cattle ratio is 60:40 with the ewes lambing an average (over five years) of 150% although last year they lambed 157%. The hoggets are consistently lambing 82-83%.

In the livestock side of the business, all progeny born on the farm is finished and in the case of the cattle, finished fast on an all-grass system before their second winter.

Michael says the first of their bulls go on to the truck weighing 800kg liveweight as early as January and the farm system is set up so all cattle are sold prime over summer and autumn.

Last year the cattle generated an income of $130/stock unit and the five-year average is $125/su.

Fast forwarding genetic gain

The artificial breeding programme has been a game-changer for the family, giving them access to the best genetics at a cost of $70-$100/cow.

“It is one of the best tools you can have,” Michael says.

While they started out by just artificially inseminating the yearling heifers using cheap straws, they now AI the whole herd and while it is a lot of work for four days, the reward is in a tight calving pattern and fast genetic gain.

“The herd will jump forward ten-fold because you are using the best of the best genetics,” he says.

The yearling heifers are the first to be AIed on September 15, the mixed-age cows on October 1 and the R3s two weeks after that.

Michael runs the cows in smaller mobs for ease of management at AIing, as all but the yearling heifers will have calves at foot.

The calves need to be drafted off four times over the process, but Michael says they set up for it and it is a system that works well.

They will then use a follow-up bull, often from the stud from which they sourced the AI straws.

Michael says they expect an AI hit rate of 60-70% across the whole herd.

“There is a bit of an art to it.

“You’ve got to look after your animals and keep the feed consistent.”

At pregnancy scanning, they will also foetal age and this allows them to identify the AI, first and second cycle calvers and manage them strategically. This helps make the most efficient and effective use of feed resources.

Focusing on growth and yield

When selecting genetics, Michael says they have been pushing for extremes in 400-600-day growth rates to maximise carcase weights when the animals are processed from 18 months old.

So far this year, the bulls have killed out at 355kg CW, the heifers at 255kg CW and the steers 330-340kg CW.

The next focus is on yield and Michael says they are now concentrating on high-yielding genetics.

“If you can yield an extra 1-2% from the same amount of feed then that can be another $150 for a 600kg bull on a $5 schedule.

“It’s money for jam.”

Michael says while they have been pushing hard on Estimated Breeding Values (EBVs) to meet Silver Fern Farms’ EQ specifications, he is coming to realise they are possibly processing their cattle too young to meet the marbling specifications.

“It’s an all-grass system and I just don’t think they are old enough to lay down enough fat at the right time.”

While some seasons they can have 60-70% of their prime cattle hitting the EQ grade, other seasons it can be as low as 10%.

Michael finds it very seasonally dependent even with the best high intramuscular fat genetics.

A tight winter, for example, can make all the difference when it comes to hitting EQ grades.

While the family uses Silver Fern Farms’ EQ grades as an indication of their genetic progress, they will also sell prime cattle to AFFCO, it’s often just a matter of who has the killing space at the right time.

At calf marking they will leave one-third of their male calves entire, based on their size. These bulls are a safety-valve in their system as they can be killed early in summer if required in case of drought.

All-grass finishing system

Pasture at Whangara comes away very early in spring, so the cows are calving in July on autumn-saved pasture. The yearling heifers calve in the first week of July and the mixed-age cows after that. Although thanks to the AI programme, the majority will calve within a short space of time.

Grass reliably starts growing by August 20 and to help with pasture quality, cows and calves are very lightly stocked among ewes with twins.

They are then rotated around pasture over summer. After weaning, the weaners will often be run behind a single wire to maintain feed quality and they will be fed a small amount of hay and balage over winter. This supplementary feed is purely to help settle them down and get the weaners used to being handled. This is particularly important for the replacements about to undergo AI.

It is an all-grass system and the Lofflersrenew about 20ha with a grass and multiple clover mix every year. A three-year ryegrass is used as a break crop, but no forage crops are grown.

Lambs are priority-fed on younger grasses and the cattle tend to get the older grasses, but Michael says they do juggle stock around depending on what needs to be priority fed and when.

“I’m a great believer in giving the right animal, the right feed at the right time.

“In this system, there are a lot of priority mobs.”

Two-thirds of the farm is steeper hill country and one-third is rolling to flat. The breeding cows spend most of their lives rotating around eight blocks on the hill country.

Best of both worlds

The cows are an Angus Simmental cross which Michael and Mandy took over from Michael’s parents, although Richard and Jenny used to include Hereford genetics in the mix. Michael says the Angus Simmental cross gives them the best of both worlds.

“You get the hybrid vigour of the Simmental and the aggressive grazing behaviour of the Angus.”

The cows are run in three mobs. The black cows, which are put to a Simmental, the coloureds which go to an Angus and R1 heifers.

With such a strong focus on growth rates, Michael feels the cows have got too big, with weaning efficiency (kilogram of calf weaned/kg of cow liveweight) sitting about 40%.

This was one of the reasons they were so pleased with the weaning efficiency of the yearling heifers this year.

“In the past two years the herd has really flipped on its head with the heifers coming through. After years of AIing, the genetics have suddenly taken off.”

Because the Lofflers run such a fast-finishing system, internal parasites aren’t a problem and although liver fluke is sometimes found at processing, Michael says they don’t appear to impact on growth rates.

Copper supplementation has made a difference to the health of the cattle, and while they started injecting the yearling heifers on their vet’s recommendations, they now inject all the yearlings and see a noticeable difference in their overall health.

Drawing on knowledge and experience

While the AI programme allows them to source genetics from anywhere, Michael believes the genetics available in this country are as good as anywhere for systems such as theirs. Over the years he has formed good relationships with stud breeders from around the country who are only too willing to share their knowledge and experience.

Michael’s father Richard has a wealth of knowledge and experience, especially when it comes to the farm. Michael is the fifth generation to farm the property and he relies on his father’s extensive knowledge of every corner of it.

“He knows where the best grass grows and where animals do better.

It’s a great asset, combining old knowledge with new technologies.

“We both love what we do, particularly when we see results like that coming through.”

The cattle are only a part of the family’s business which includes the sheep breeding and finishing, a gold kiwifruit orchard and the citrus orchard.

The family employs two full-time casuals who work predominantly in the horticulture side of the business.

From a work load point of view, everything fits together nicely, it just means there is no down time for the family. Fortunately, they enjoy the variety within their business but appreciate the simplicity and efficiency of their breeding and finishing cattle system which is reaping rewards.