Speaking at the field day, farm consultant Wayne Allan looked at how increasing the legume content of their hill country pastures has benefited the Craws’ business.

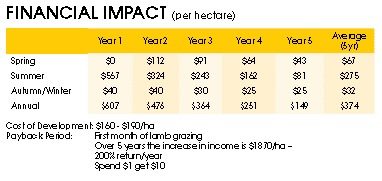

He found that every dollar spent on increasing legume content generated a return of $10 over the subsequent five-year period – or a 200% annual return on investment.

On unimproved areas, the Craws’ hill country was carrying five to six twin-bearing ewes per hectare, the average lamb weaning weight was 31kg and the ewe weaning weight was 67kg.

On the improved area, lamb weaning weight increased by an average of 1.4kg and the ewe weaning weight increased by 2kg over five years.

Over summer, the unimproved country was carrying 12 lambs/ha which were growing at 125g/day.

In the first year after development, the improved country was still carrying 12 lambs/ha but these lambs were growing at 300g/day. By the fifth year, these growth rates had dropped to 150g/day.

This is an average lift of 85g/lamb/day but this meant an addition 7.6kg/lamb.

In autumn the unimproved country was carrying 10 ewes/ha dropping to 5-6 ewes/ha over winter.

While the stocking rates numbers on the improved country is similar, the ewes are heavier going into mating and this has resulted in a 3% improvement in the lambing percentage on this country.

Wayne says the big driver of what farmers do with feed post-weaning is driven by liveweight gain pre-weaning in other words farmers have more options if lambs are heavier at weaning.

Over five years, this increase in livestock performance as a result of having more legume in the sward generated an average increase in the gross margin by $375/ha.

The cost of development- which in this case is just the cost of chemical and application- was $160-$190/ha.

This means that within the first month, six weeks of lamb grazing, the cost of the chemical and development has been paid for.

“So pay-back is pretty quick.”

This lift in production is driven by an increase in the ME of the pasture which drives lactation and liveweight gains in both ewes and lambs.

In theory, an initial lift in the ME by two will add 200g/day in liveweight gain to pre-weaned lambs.

It also means a high proportion of feed goes into growth and less into maintenance.

A lamb growth rate of 300g/day means more energy is going into growth making for a far more efficient system.

A 100g/day liveweight gain is generating a return on 18c-25c/kg DM (depending on the buy-in price), a 200g/day liveweight gain is generating 28-38c/kg DM while a 300g/day growth rate is returning 33-46c/kg DM.

“This is all driven by the quantity and quality of the feed we put down their throat.

“Don’t underestimate the power of quality feed,” Allan says.

Rob and Sandra Faulkner: Innovation Farmers – Gisborne

The Faulkners farm 600ha of hill country near Gisborne and aim to increase the clover component in their hill country pastures from 5% to 30%. This will increase weaning weights and provide more lamb finishing options.

In April 2016 they flew Arrowleaf clover seed onto a designated area at 12kg/ha along with slugbait. After sowing, stock was run over the sown area to push the seed into the ground.

The sowing was timely and was followed by a good rainfall. Rob says if they sow too early in autumn the seedlings can fry in hot, dry conditions.

In that first year they grazed the clover between August and the end of September before locking it up. The clover produced 10 tonnes of drymatter/ha but the Faulkners let it seed and then used cows to graze down the stalk.

This initial crop gave the couple the confidence to sow another north-facing block in this clover in autumn last year.

The paddock was sprayed with glyphosate and an insecticide and it was a matter of waiting until there was sufficient moisture in the ground before they flew the seed on.

“It was a matter of getting all the ducks lined up with the weather, helicopter etc, but it’s really important to get those ducks aligned and not to be too impatient,” he says.

The seed was not flown on until May 12 and while this was later than ideal, they needed to wait to ensure the moisture was there.

“It’s not like going into a cultivated paddock.”

The seed struck, and despite insecticides and slug bait, the crop did suffer a small amount of insect damage. The paddock was grazed in late August and shut-up in October to allow plants to seed and the seed to set.

He has found the most challenging part of this B+LNZ Innovation Farm project has been in getting the legume established.

“Once you get that right everything else takes care of itself, but it does require a lot of forward planning.”

The resulting increase in clover in the pasture has allowed them to increase the stocking rate from seven to ten ewes and the weaning weight of these ewes lifted from 63kg to 67kg. At $2.20/kg, this increase in stocking rate and weaning weight generated an extra $504/ha.

FORESTRY BLOCK

The Faulkners have forestry blocks on their farm and the harvest of one block in January 2016 gave them an opportunity to grow clover in the cleared area.

The area was burnt in late March and fertiliser, seed and slug bait applied in mid-April.

A good strike allowed the area to be grazed in August and it was shut-up for seed-set in October.

In July 2018 the area was sprayed with glyphosate at 2 litres/ha to reduce grass competition and the Faulkners lambed ewes on the clover-rich pasture in August.

Trees will be replanted on the block this year, but Rob and Sandra will keep grazing the area. Rob says the income generated off the block by livestock will pay for the trees and the nitrogen fixed by the clover will help the trees grow.

Pete Swinburn & Suzanne Hoyt

Pete and Suzanne farm 1480ha (1276ha effective) of easy rolling to moderate hill country near Flemington, south of Hastings in a partnership. They run breeding ewes and finish both lambs and bulls.

The partnership has struggled with ewe performance on hill country and they have not been able to lift weaning weights above 26kg.

To improve performance, they joined the B+LNZ Innovation farm programme and looked to increase the legume component of their hill country pastures by using spray and seed to establish new and spray and management to increase the content of resident sub clovers.

In April 2017, Pete sowed 12kg/ha Arrowleaf into a 4ha block that had only been producing 4-5t DM/ha/year and had low legume content.

By July that block was growing 19kg DM/ha/day – a huge increase on typical winter pasture growth rates of 8-9kg DM/ha/day.

Between April and December 2017 that block grew 10.5t of clover.

The block was locked up for seed-set in October and the clover dropped an estimated 1379kg of seed/ha – this was from the initial seeding of 12kg/ha.

Between September 27 and November 11, 2018, the improved pastures grew 82 kg DM/ha/day compared to the unimproved grass which grew at 22kg DM/ha/day.

Molybdenum and sulphur were identified as being limiting factors in legume production, so molybdenum is being applied to the whole farm.

Pete says one of the challenges with Arrowleaf clover is dealing with the trash after seed-set.

Richard and Becks Tosswill

Richard and his wife Becks farm a 622ha effective hill country farm in the Wairarapa. Only 9% of the farm is cultivable, so they need their hill country to be as productive as possible. They run 3000 Texel cross ewes, replacement hoggets and 100 Angus breeding cows.

Richard says they run a simple sheep system by aiming to kill a high per centage of their lamb crop prime at weaning.

As part of the innovation farm programme, they aim to increase the legume content of their hill country pastures, but do this with minimal use of sprays. Richard says they have planted a lot of trees, hence the reluctance to spray, but thistles are also a problem, so they don’t want to open the sward up too much.

Their trial work looks at both establishment and management.

In May 2017 they applied a light spray on one area to knock back the grass before clover seed – a mix of varieties – was hand-spun on to the area. Stock was used to push the seed into the ground.

On another area a mix of subterranean and white clovers was oversown on to an area of hard country with great success.

In this area the legume component of the sward leapt to 72%, compared with the control area which only had 25% legume.

On areas which were actively managed to encourage the resident sub clover, the clover content of the sward increased to 42%, compared to 11 in a control area.

Last year they trialled different varieties of sub clover. These were sown in April in less than ideal climatic conditions and slugs were also a problem – but Richard is confident they will see some positive outcomes.

They are also running a trial looking at the use of micronutrients on legumes.

Richard is excited about the potential of increasing legumes in his pastures and the impact they will have on farm policies, but says it is a matter of being patient and focusing on the long-term gain.

“But it has been rewarding and exciting so far.”

He says he had never really understood the timing of germination and the change of grazing management required to allow clovers to set-seed and germinate, but this is critical in building legume populations.

Hugh Dampier-Crossley

Koromiko, North Canterbury Hugh and his wife Lucy farm a 2288ha hill country farm near Cheviot.

Hugh was part of Beef + Lamb New Zealand’s Sheep for Profit Partnership programme and saw how the topperforming farms (all on flat country) were utilising sub clover to drive early-season sheep production.

Determined to emulate this on hill country, Hugh started including 10kg/ha of sub clovers (both early and late flowering) in his seed mixes with great results.

The increase in feed quality in conjunction with a change in genetics (Corriedales to Romneys) saw lambing percentages in their 4300 ewes lift from 105% to 150. Lifting cattle numbers has also helped the sub clover flourish by removing competition from grass.

In 2016 Hugh and Lucy took part in a Lincoln University-led Sub 4 Spring trial. The trial was run on what Hugh describes as the worst block on his farm – and in the grips of the North Canterbury drought.

“You couldn’t have asked for worse conditions,” says Hugh.

Fertility was poor on the 30ha block with Olsen P of 7-14 and pH of 5.2-5.3.

The block was grazed hard before three different chemical treatments were applied.

They were one litre/ha of glyphosate, 6L glyphosate and Reglone. These chemical treatments were repeated three times and compared with a “control” untreated area.

The best result was achieved on the untreated area.

Seed was flown on April and 1200 ewes run over it to tread the seed into the soil.

Normal autumn rainfall never came and the seeds didn’t strike until July. Hugh had written the trial off as a disaster but grazed the area before letting it seed in November.The block was grazed by cows and calves to knock back any grass, but once the autumn rains came, the quantity of sub that came through was “mind-blowing”.

At the start the trial the amount of clover in the sward was 8%, at the end it was 47%, with sub making up the majority of clover.

Hugh says the trial highlighted the need for good grazing management to enhance sub production.

He says it is important to remove tag over January and February to open up the sward to allow a good strike of sub clover seed.

After rain in autumn, Hugh will keep stock off the area for two to three weeks before grazing as a normal part of the rotation.

Over winter he grazes the area hard with cows and this sets the area up for good clover production in August, September and October.