A Game of Two Halves

When 70% of the workload in running sheep is generated by the wool they grow, it is unsurprising farmers are exploring new breeds that grow less fibre or naturally shed it completely. Tony Leggett investigates two farm businesses on different sides of the field. Words Tony Leggett.

Staying with Wool

Wairarapa sheep and beef farmers Pattie and Tony O’Boyle are the first to admit their patience has been tested when it comes to the return for their strong wool clip in recent years but are determined to stick with producing wool and not be tempted by the option of shedding breeds.

“We have owned Marangai Station for about 16 years and when we first took over, our wool was delivering a net gain of more than $100,000 in our annual accounts. It’s a very different story today when we’re making a net loss or struggling to get to breakeven levels,” Pattie says.

On a recent trip to the United Kingdom, they took time out to visit one of the oldest woollen cloth makers in the country, Abraham Moon, at Leeds in northern England.

The visit was an eye-opener for the O’Boyles and their son Patrick. Abraham Moon has been weaving woollen fabric for 185 years and among its customers is iconic coat maker, Barbour, with its trademark woollen lining.

“We were fortunate that a team from Abraham Moon had been to our farm earlier in the year so we were able to get in front of their marketing, operations and sustainability executives and get a tour around their factory,” Tony says. Abraham Moon buys mostly 29-micron lambs’ wool from Australia, South Africa and New Zealand farms. “They were aware our sheep numbers in NZ are falling, but unfortunately they also told us they are able to source all they need from Australia and South Africa,” he continues. “They were very interested in our sustainability story including our recent accreditations,

NZ Farm Assurance Programme Plus; carbon mapping through Net Carbon Zero by Nature and the Wool Integrity Programme through PGG Wrightson,” Tony says.

The biggest challenge they discussed was the quality of the wool presented to them, particularly impurities in the scoured wool arriving at their plant. “We’ve actually double-downed on wool by investing in renovations in our wool shed and a new press so we can ensure our wool is prepared to a very high standard,” Tony says.

He feels the current structures grossly under-value wool, in a similar way to the coffee bean market before it adopted Fair Trade rules which boosted grower returns to a profitable, sustainable level. “There are at least seven changes of ownership as wool makes its journey from sheep’s back to a consumer’s hands. We produce an amazing product yet the system is not set up to reward growers well enough for it,” Tony says.

They have recently moved away from selling their wool at auction, preferring to contract supply Wools of NZ for its burgeoning wool carpet and tile business. It has already had an impact on price after the Marangai Station second-shear fleece wool recently sold for $3.30/kg clean, their best result in several years but say they still need another $1/kg to break even.

Converted to shedding flock

North Canterbury farmers Andrew and Sara Heard were early adopters of shedding genetics 15 years ago and say they have never looked back.

“They have an edge on other breeds of sheep when it comes to some of the major challenges facing our sheep industry,” Andrew says. “By fully shedding their wool, the workload is so much less than other sheep breeds, and that has huge appeal for many farmers. We do no shearing, no crutching, no dipping for fly. “They also seem to be more tolerant of worms and facial eczema, they lamb easily and bearings are rare in our ewes.”

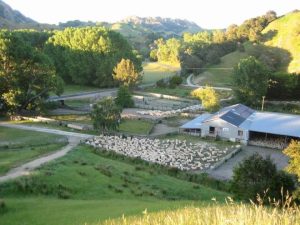

Staying with fully shedding sheep was an easy call to make when they bought into a new equity partnership in 2022 near Hawarden in North Canterbury.

Waitohi Peaks is 500ha, comprising 300ha of hill country and 200ha of downs and flats, and runs about

3,000 stock units. The Heard’s have

a commercial shedding flock of 700 ewes, and their Waitohi Peaks stud

flock has 700 ewes which are all DNA profiled and recorded in Sheep Improvement Limited.

They have just come through another lengthy dry spell for the Hurunui district, but managed to retain all their capital stock sheep. “We’ve been feeding out since February. It’s been a challenging time but our stock have come through in pretty good order all things considered,” Andrew says.

They are in their third season selling rams and this year expect to market about 150 mostly two-tooth rams. Their clients come from as far north as Northland and as far south as Southland. Wool prices are often discussed during ram selling season as clients are making their selections. “We often ask our ram clients what value crossbred wool would have to reach before they would reconsider changing back to wool again, and the numbers range from $7/kg to as much as $14/kg,” Andrew says. Those clients suggesting a number at the top end of that scale are including an allowance for the labour component of the extra work wool creates on a farm.

“There are two shearings, and crutching, dagging, drenching and dipping sheep for fly to consider. That’s not taking into account the time and cost of having ewes losing condition off the paddock in the yards while those jobs are done,” says Andrew. “They are a very resilient animal to farm. They seem to have a natural tolerance to worms and facial eczema.

“We’ve started testing that tolerance to facial eczema challenge because we’re selling more stock into the North Island these days, and farmers are wary of how the progeny from our rams will perform.”