Owl Farm follows the wagon wheel

By Louise Hanlon

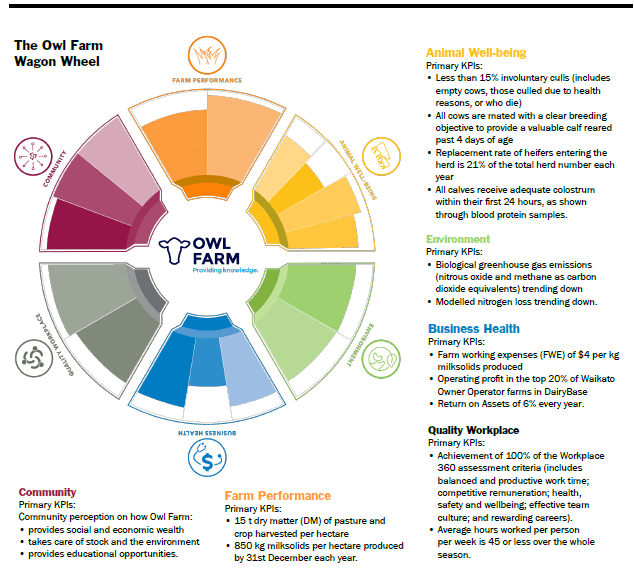

The team on Owl Farm, the demonstration farm owned by St Peter’s School Cambridge and run as a joint venture with Lincoln University, have their eyes firmly fixed on the future and all the signs indicate that costs are only going to rise. However, planning, while utilising the KPIs set in place in their “wagon wheel” framework, is helping them to set a viable direction.

The “wagon wheel” is central to planning and monitoring on Owl Farm. Jo Sheridan, Owl Farm’s Demonstration Manager, is an enthusiastic supporter of the wagon wheel approach.

“I strongly believe all farmers should be implementing it in their business,” she says. “It is a simple tool for visualising and categorising your farm’s KPIs. Profitability is fundamental for all of our businesses, but, equally for us on Owl Farm, taking care of our animals and the environment, providing a quality workplace, and meeting community expectations, are also central to the way we operate and have an impact on our decision-making process.

“The wagon wheel helps us to get a firm fix on the direction we want to head.”

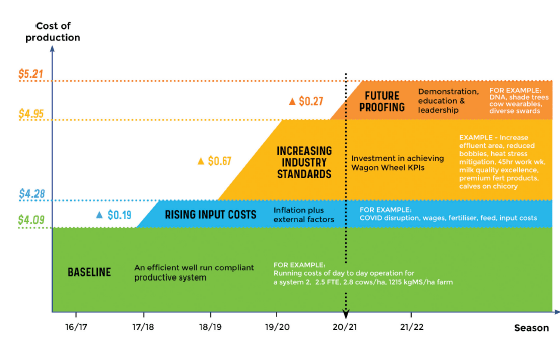

A recent analysis of current and future business costs has given the team a good feel for how they are progressing, and the impact of their plans on Owl Farm’s profitability.

They use DairyBase as a benchmarking tool and the 2020/21 analysis showed Owl Farm’s farm working expenses (FWE) were $4.60/kg milksolids (MS) – compared to $4.62/kg MS for the top 20% Waikato farmers (based on their operating profit).

Their 2021/22 budget provides an in-depth breakdown of where they are investing their funds and the outcomes they aim to achieve in each of the key areas identified in their wagon wheel. They have divided their goals up into categories, each with an attendant impact on their cost of production (see diagram 1).

Baseline

The first category, Baseline, includes the costs of running a well-managed, compliant business, with the main emphasis on achieving profitability, without focusing on environmental or animal wellbeing outcomes. It includes the costs of, for example, purchasing the supplements needed to achieve production targets, and meeting basic fertiliser, cropping and regrassing requirements. If the business is simply run at this level it is predicted to produce 175,000kg MS at a cost of $4.09/kg MS.

Rising input costs

The next category, rising input costs, incorporates the impact of increasing costs, including inflation. This season increasing costs are having a larger impact than in a typical year, and are estimated to add an extra $33,300 of costs to the budget ($0.19/kg MS). The main areas affected are: labour costs, supplement and fertiliser prices, and fuel and freight costs.

Increasing industry standards

The third category, increasing industry standards, is where Owl Farm is meeting the wagon wheel KPIs which aim to cement their licence to operate and remain profitable in the more stringent regulatory times ahead of them.

Jo is keen to encourage farmers to take a good look at this area on their farm.

“There is anxiety in the industry about what regulations will mean for the viability of farm businesses,” she says, “but we feel that as long as farmers prepare early there is scope to still operate profitably and room for optimism about the future.”

Investment to meet increasing industry standards will be an ongoing cost for the farm, but they are looking for a win:win

situation, where the strategies they implement will also provide financial benefits. Included in this category are:

Animal wellbeing

- Tackling lameness issues. Improving the race infrastructure and implementing a range of another initiatives, under the auspices of the Healthy Hoof programme (which is administered by DairyNZ). The outcome to date is a reduction in lameness from 34% to 13% of the herd, with a target of reducing it to below 12%.

- Purposeful lives for calves. Using sexed semen and heifer synchrony, and offsetting the cost by reducing the replacements reared and selling any excess high BW heifers. Wagyu semen has also been used to produce high value beef calves for sale at around 13 days old. This strategy increased purposeful life levels from 34% in the 2018 season to 70% in 2021.

- Grazing heifers at home. Using chicory and supplements to feed calves optimally so they meet target liveweight gains, which has the knock-on effect of reaching reproductive and production targets, decreasing replacement numbers, and decreasing grazing costs. Only 2% of the R2yr heifers were empty in 2021, in comparison with 6% in 2020, and 10% the season before. On average, the heifers weighed 224kg at 9 months old this season (210kg in 2020) and 327kg at planned start of mating (322kg in 2020).

Environment

Reducing biological GHG emissions. A range of strategies have been implemented including: reducing the

stocking rate (from 2.95 to 2.8 cows/ha) and increasing cow efficiency through breeding high BW cows, with per cow production increasing by 2.5% over the last six seasons (to 440kg MS/cow/year); reducing imported supplement levels; using no-till cultivation for crops; and retiring unproductive land and planting it up. The result has been a reduction in biological emissions of 7% over the course of the last six seasons.

- Reducing annual nitrogen fertiliser use. This is down from 161 to 138kg N/ha, alongside increasing the amount of clover planted.

- Decreasing nitrogen loss. The strategies here have included: extending the effluent spreading area and installing a larger effluent pond (which gives application timing flexibility); improving the fertiliser strategy by using different products, and optimal application timing, placement and rates. These strategies have decreased the nitrogen loss from 40 to 34kg N/ha/year over the last six seasons.

- Wetland development. Owl Farm has two natural fenced wetlands and a constructed wetland. NIWA water quality measurements from the constructed wetland showed a 63% removal of nitrates from its catchment area.

Quality workplace

- Two key goals in this section of the wagon wheel are to meet Workplace 360 requirements, and to ensure each employee’s average working week sits at 45 hours or below for the year. To this end, there has been a significant investment in technology, including: automatic cup removers and teat sprayers, Protrack, and most recently Halter; alongside shifting the spring peak which has reduced the work load during the busy time of the season. To date the working week has reduced from 50 to 46 hours.

The changes in this category are budgeted to cost about $117,030 ($0.67/kgMS). It is expected that many of the strategies included in this category, and their costs, will become part of business as usual for Owl Farm which is why they have focused on debt reduction and improving business resilience. They have updated their long term FWE target ($4.60/kg MS) to reflect the rising cost of meeting industry standards and are driven to ensure the farm continues to deliver across all of its financial metrics.

Future proofing

The fourth, and final, category is future proofing. The strategies included here may not have associated benefits in cost reduction or increased profitability, but are considered part of meeting the wagon wheel KPIs and fulfilling the farm’s demonstration role.

This year’s excellent payout is allowing the team to tackle some of their discretionary farm goals without jeopardising the business’s financial health, and these strategies include investing in:

- DNA sampling the calves which will allow selection for specific traits in the future.

- Introducing Halter to allow improved animal management.

- Planting ecologically diverse species and trees for shade. The planting plan spans three years at a cost of $15,000/year.

- Including Ecotain plantain in all new pastures and oversowing it into existing swards.

This category of strategies is budgeted to cost $46,700 ($0.27/kg MS).

Drilling down into the costs in this amount of detail has given the Owl Farm team the ability to move forward confidently into the future and is a worthwhile exercise for all farmers to undertake.

- More information about each of the strategies and their outcomes, which will be regularly updated, can be found on the farm’s new website: www.owlfarm.nz.