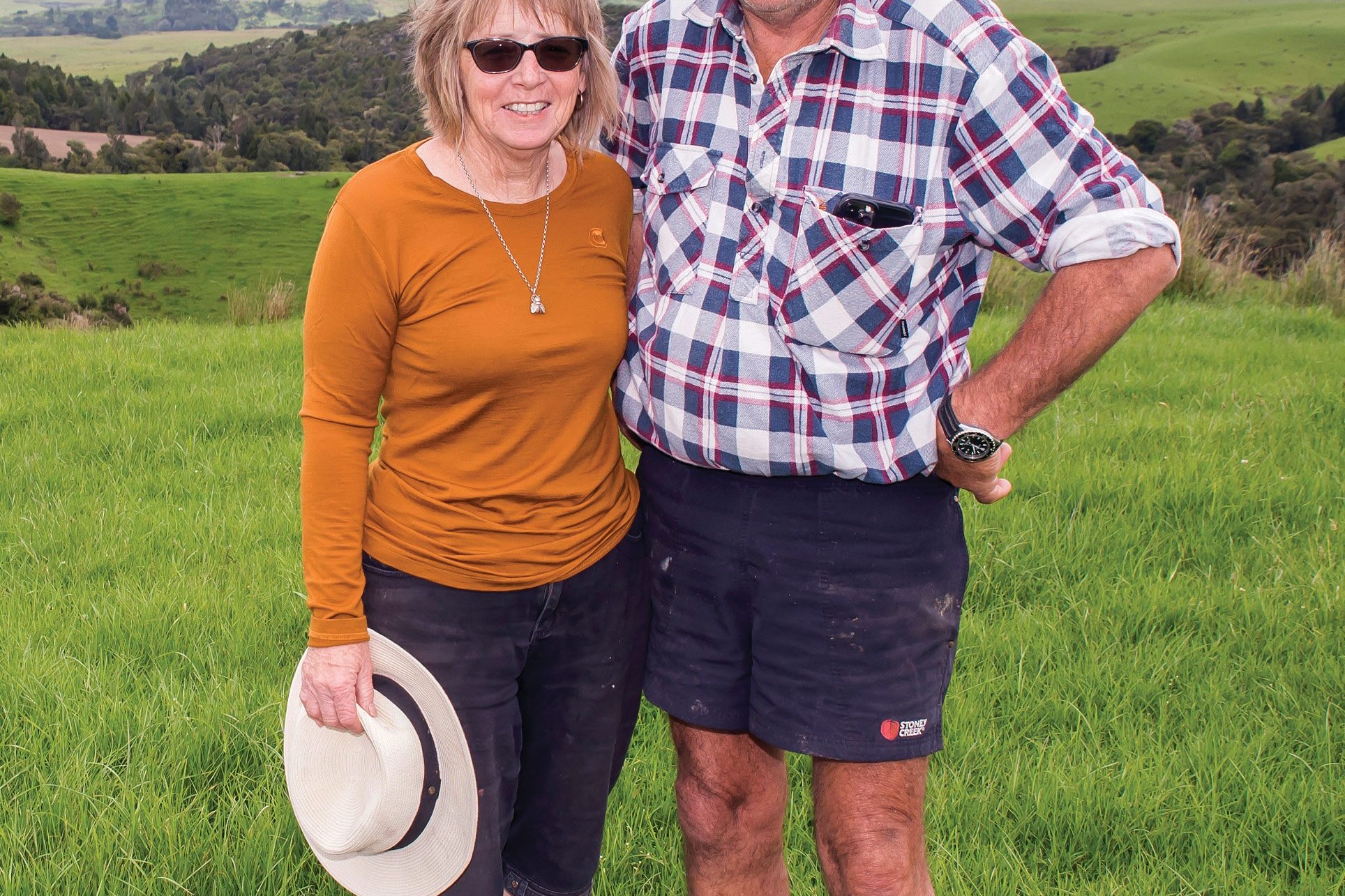

A South Island trip more than 20 years ago led not only to an enduring friendship but two passionate Northland advocates for Merino genetics. Story by Glenys Christian. Photos: Malcolm Pullman.

Despite challenges from weather and animal health issues, Bay of Islands’ farmers Neville and Linda Lewis are keen to earn more from their wool clip.

They also want to get other farmers in their area farming sheep.

Five years ago they started using Merino-Romney rams north over a percentage of their 1500 Romney flock.

The best of 130kg earned $11/kg, so buoyed by these results for the past two years, six to eight quarter bred Benmore Station rams have come on to the farm to continue the shift to a finer clip.

There are now about 300 sheep on the farm with a touch of Merino with all of their 900 white-face sheep going to the breed this year.

Being 30 minutes drive inland from the Bay of Islands and three hours south of Cape Reinga, they know they are at the other end of the country to be doing what they’re doing.

“But it’s worth a try,” Neville said.

“We have hit some good prices.”

Neville’s father, Harold bought their 363-hectare farm, initially H. Lewis & Sons Ltd in 1972, meaning the half century mark is fast approaching in February. Another 159ha was bought in 1982 and is now run as Stoney Creek Valley Farm, near Okaihau.

“My father was a shearer and always had sheep,” Neville says.

He describes the farm, which covers flat to rolling to steep country, as being derelict when they arrived, with a lot of development work to be carried out, clearing gorse, manuka, fern and blackberry, putting in fences.

About 380ha is effective.

“It looks nice now.”

Following in his father’s footsteps after taking over the farm, he’s always been interested in wool. And Linda always wears wool in preference to microfleece.

Taking their family south to tramp the Kepler Track saw them make a detour to Lake Middleton, mainly because it was Linda’s maiden name.

“We didn’t know it existed,” he says.

That saw the couple buy a section and build a house which was destroyed in last year’s Twizel area fire.

They became friends with Bill and Kate Sutherland, owners of nearby Benmore Station and in 2004, after Bill had surgery putting him out of farming action for six months, Neville was asked to work there as a general hand with Andrew, Bill’s brother, and his wife Deidre.

Years later after another visit down south, talking over a beer, Bill asked Neville about trialing some of their halfbred rams. So when he came back to the north he started to think seriously about the benefits of introducing those genetics on the farm. He had regularly complained to Bill about the poor crossbred wool prices he was receiving and the direction the strong wool industry was taking.

“Crossbred wool is hopeless,” he says.

“It used to pay for the farm’s fertiliser but now it doesn’t even pay for shearing. And when you’re out of pocket for that it makes it hard. So that’s how it started.”

In the first year of their trial five years ago Bill sent six halfbred Merino-Romney rams north to be put over a percentage of their 1500 Romney flock just to see how they stacked up.

“We kept it quiet because we knew we would come up against a lot of criticism,” Linda says.

“When you mention Merinos, Northland sheep farmers throw their hands up in the air and say, ‘footrot’.”

They fully expected to have problems but despite humid and wet weather and some boggy pastures it wasn’t an issue.

Ironically lameness had occasionally been a problem in their Romney and blackface rams.

A further six halfbred rams came on to the farm the next year with the quality of first-cross weaned lambs and wool clip both giving them a pleasant surprise.

Bill came north to class the 130 kilograms of wool produced which tested at about 26 microns.

“That showed the potential,” Neville says.

About 300 five-year-old Romney ewes are bred to terminal sires of either Charollais Texel-cross or Suffolks, lambing at the end of June. All lambs are finished going off the farm in October or November at an average of 18kg off their mothers.

The main flock follows up with lambing in the first week of August. None of the ewes have been bred to straight

Romney rams this year in order to get more lambs with some Merino genetics as rapidly as possible.

“If we get more on the ground, we can get a better selection to breed from,’’ he says.

Linda says Neville grows “seriously good” sheep and has continued his mantra of trying to do the basics well. Putting his well-trained eye across an unfamiliar breed of sheep was a learning curve and something he had to adjust to.

It’s also been a struggle having the numbers to select from in order to make the improvements they would like to see.

“We’re trying to keep the numbers up so we’ve kept some we wouldn’t normally breed from,” he says.

“That’s been a bit of a challenge.”

Northland’s not a good place for any sheep to be in summer due to viral pneumonia, facial eczema and its usual drought conditions. But facial eczema hasn’t been the issue they thought it could have been.

Last year’s lambs went into the spring with very little feed, but this year’s spring and early summer’s unusually high rainfall has meant a test of a different type.

“We’ve had a serious amount of rain which we haven’t had in recent years,” he says.

In October up to 650 millimetres fell on the farm when usually they would expect around 250mm.

“It was horrendous. The weather could be our biggest enemy as dry weather is good for halfbred Merinos. But this spring is one of the wettest we’ve had and as a result we had a huge amount of grass.”

Hoggets usually shorn in October were only shorn in November due to the continual rain.

Getting sheep dry was a challenge.

“In hindsight we should have shorn earlier, with the wool clip resulting in a bit of colour which is scourable. We just have to adjust.”

They used to shear the ewes at weaning along with the lambs in order to put weight back on to both, never worrying about the length of the wool.

Bill’s suggestion was to wait in order to get longer lambs’ fleece length of higher value. But delaying until March or April meant they ended up with fleece with a lot of vegetable matter, so now they’ve brought shearing forward to February which has seen a correction of that problem. The clip is now down to an average of 26 microns, coarsening as the sheep age.

But the timing of shearing remains an issue. With unpredictable weather getting sheep dry with shearers organised can be a challenge.

In the past the consistency of quality wool handlers has been an issue as with the strong wool price so low some farmers just swept it into a heap. And with farmers turning away from sheep there wasn’t enough work for wool handlers so they headed south for work.

“Wool classers up here are scarce, but we have been lucky in the past to have had one who worked in Australia with mid-micron wool,” Linda says.

“You have to work your butts off in the shearing shed because you’ve got to do things right. Presentation is key. It’s a lot more work but if you get the returns, it’s worth it.”

Neville says they can grow good quality, white, bright wool.

“You need to get management and shearing right to optimise soundness, colour, length and also get less vegetable matter.”

As well as the sheep, 180 Angus cows are run using Angus bulls and some terminal Charolais.

“We used to finish them on another property but now we just finish heifers and sell the rest store,” Neville says.

A pasture improvement programme has been underway for the last four years. On one large subdivided 30ha paddock which has recently been fenced and provided with a water supply, chicory and raphno have been used which has put good weights on their lambs.

“It does seriously well in Northland,” Neville says.

After cropping, the land will be sown in permanent pasture, a ryegrass clover mix.

Their fertiliser programme, which has been sparse because of the lack of wool income in recent times, is 94 tonnes of combined of serpentine super, potash, selenium, molybdenum, sulphur and Sustain which goes on as maintenance with top-ups of 50t of super 10, DAP, potash and boron. The soil pH ranges from 5.8 to 6.1 with Olsen P from 7 to 27.

Their hill country has not seen fertiliser for many years.

About 140ha of the farm has been fenced off and retired, comprising some virgin bush and regenerating native bush. Wetlands have also been fenced with manuka, flaxes and other natives and poplars planted all through these areas.

Neville and Linda have always allowed four-wheel drive and motorbike enthusiasts as well as horse trekkers for community fund-raising events to use the property as long as they respect it.

In the last 10 years two and a half kilometres of the Pou Herenga Tai Twin coast cycle trail has been put through their land following the Utakura river. A number of local landowners grouped together to fence off bush and plant flax to attract tui with the aim of making the route from which runs in four sections from Opua to Horeke, one of the best cycle trails in the country. Neville is a trustee on Pou Herenga Tai Twin Coast Cycle Trail trust and they also offer off-grid farmstay accommodation.

For the future they strongly believe halfbred Merinos have more to offer the north.

“Other farms in the north have tried purebred but it’s not been successful,” he says.

He’s a keen member of Last Sheep Standing, a Red Meat Profit Partnership (RMPP) which has a like-minded membership of seven local farmers.

“They’re all interested in what we’re doing,” he says.

“But there are not enough enthusiastic farmers producing wool up here and that’s frustrating.”

With larger properties employing managers the interest is stronger in meat production, as they have to justify why they would try something different. But he’s still keen for some of them to give Merino genetics a try.

Their wool, strong and mid-micron, is sold through New Zealand Merino.

“It’s great being able to see results in testing from micron to colour and vegetable matter, resulting in better management all round,” he said.

“Being ZQ accredited we know where our wool is going into the world market and what it’s used for as well as those buying it knowing where it has come from.”

Covid-19 has made it difficult for NZ Merino representatives to come and visit in recent times.

He believes the wool on lambs on the ground now, if it meets the right specifications, will return $10 a kilogram.

“It’s proven to be worth doing.”