Launching a farm beef brand not for the faint-hearted

It takes bucket loads of passion, massive determination and hours of dedication to achieve the dream of breeding, finishing, processing and retailing only beef cattle from one source. Words Tony Leggett.

Many have tried and folded under the intense pressure of maintaining year-round supplies from a spring calving herd and finding a viable market for the more than 80% of each carcase considered secondary cuts.

One of the few farm brands in New Zealand sticking to its belief of only selling its own beef is Matangi Angus, managed by Jamie and Nicky Gaddum in Hawke’s Bay.

“We operate from breeding for eating quality right through to delivery to our clients with our own chillers, processing facility, and retail shop,” says Jamie. “I think it’s pretty rare from what we can see.”

Matangi Angus Beef is a partnership between Austrian entrepreneur Robert Haselsteiner, who bought Matangi Farm in 2015, and the Gaddums who own a nearby finishing farm and manage the two properties together.

Haselsteiner was frustrated that he could buy premium New Zealand beef while he was home in Austria for several months each year, but struggled to find the same quality meat while he was living here.

“It kind of makes sense because we export all our premium beef, so our goal was to produce the best grass-fed Angus beef in New Zealand for New Zealanders. It doesn’t just happen by fluke.”

In 2016, they began by looking for breeding stock that could deliver progeny that met their standard for eating experience and managed to buy 28 registered cows that were in the top 1% for intramuscular fat within the Angus breed in New Zealand.

“Our goal was to produce the best grass-fed Angus beef in New Zealand for New Zealanders.” – Robert Haselsteiner, Matangi Angus Beef

At the same time, they explored management policies for their cattle to produce high-quality grass-fed beef and started working closely with Rissington Cattle Company to source their sire genetics.

“We found keeping smaller mobs and making sure cattle are fed every day of their life and treating them quietly all made a difference to the eating experience,” says Jamie.

When the progeny from their first pilot programme were slaughtered in 2019, and graded by an independent grader, they knew they could achieve their goal of selling premium grass-fed beef produced on their land to New Zealand consumers and restaurants.

At that point, the Gaddums admit they were in two minds about jumping into a branded beef business.

“I’m trying to think of anyone that said ‘good idea’,” Jamie says. “I think everyone said don’t do it, you’re a farmer, you should stick to what you know!”

But they leaned on Haselsteiner’s business experience and his desire to create a unique brand to showcase their premium grass-fed Matangi Angus beef. They took confidence from the feedback on their first consignment of animals that were processed and offered to local chefs in Hawke’s Bay.

“It was at that point that we got the feedback saying this is a really great product and it was like, okay, we’re on to something here,” Nicky says.

It was still early days and they were using a contract butcher to break down each carcase to their specifications for the consumer and restaurant trade.

They set up a website and employed a sales representative in Auckland to begin selling product to restaurants and other food service businesses.

“We put our energy into the online shop in the first instance,” says Nicky. “And in hindsight, that was a really good move because Covid hit and we could continue trading through all of that.

“That was the point where online stores really came into their own and people started to see that you can buy a perishable product online and have it delivered all over the country within 24 hours.”

They are on their second website now which was custom-built by an Auckland company and Nicky is more involved in the business to run the marketing, manage orders and website activity.

When Cyclone Gabrielle hit in early 2023, both farms were hit hard and they were forced to park the business for a few months while they dealt with the recovery phase.

They had to deal with the loss of all their meat in the chillers at their contract butcher’s premises which had lost power. But the impact of the cyclone proved to be a turning point in development of the Matangi Angus brand and its future.

“We had to decide – do we just pack up and stop here, or do we actually turn this into a long-term sustainable business and bring all of the processing in-house and have full control so that we can’t get hit like this again?” explains Nicky.

After evaluating the options for three months, they decided to build their own butchery and processing facility in Hastings and found a site about five minutes from the Progressive Meats plant where the cattle are slaughtered.

It was a deep-end experience for Jamie who project-managed the build over the following eight months, and sourced all the equipment and recruited staff to run it.

“Financially, it’s a big step,” says Jamie. “We had to lease a building and invest in making it compliant for food processing.”

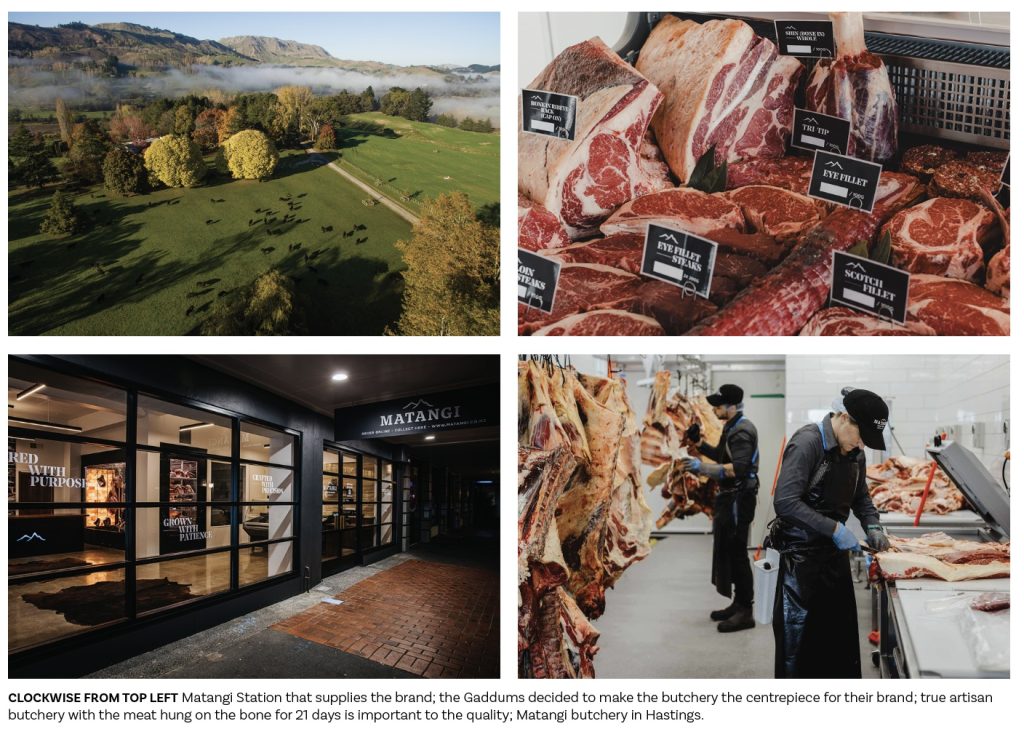

The Gaddums decided to make the butchery into a centrepiece for the Matangi Angus brand where they could showcase their beef, and invite chefs and clients to experience the farm and butchery.

“The butchery and retail store completes the vertical integration right through from farm to fork and that’s a huge plus for us,” Jamie says.

“We wanted to return to true artisan butchery. For this reason, our beef is hung on the bone for 21 days. This helps produce a more tender product that is full of flavour. We also do further dry ageing to order using our customised dry-ageing cabinet.”

Jamie says that as a farmer, the satisfaction of growing a cattle beast from birth to seeing it sold directly to a consumer as an amazing meal experience is huge.

“We get feedback coming back to us and it really makes it worthwhile,” he says. “I think looking back, it’s a rocky road, but I’d do it again. Definitely.”

Looking ahead, the Gaddums say they will continue to focus on quality, not quantity and they are content that the amount of beef they produce is constrained by the 800ha of farmland they manage.

They currently have a 250-head Angus cow herd and operate a split-calving system with cows calving in spring or autumn to extend their supply of beef to more than 10 months of the year.

They continue to supply mostly frozen product during their 6–8-week off-season, but they have found the hiatus also creates a build-up of sales momentum once the supply of fresh beef comes back on stream.

“Think about Bluff oysters – there’s a season for them, or strawberries or asparagus,” says Jamie. “Clients just accept it and then they get excited when we’re going to open up again, so it certainly hasn’t been a downside for the business.”

One of their next goals is to extract more value from the whole carcase, not just the 16–20% which are primal cuts, popular with restaurants and their online customers.

Another is to build foot traffic through their retail butchery and continue the growth in online sales through their website.

NZ online sales fuels export expansion for Green Meadows Beef

Taranaki is home to one of the longest running farm beef brands, Green Meadows Beef, owned and operated since 2012 by the Carey family from Ōpunake. Chief Executive Nick Carey says the brand was established by his father Joe who simply wanted to get closer to consumers and improve his farm-gate returns by gaining a bigger slice of the retail margin for his Angus cattle. Green Meadows embraced online selling and its early success has fuelled further growth over the years. These days, the company employs 35 staff, sells to both the domestic and export markets, and is further processing meat through its own ‘value-adding’ facility.

“It’s evolved a lot over the past 12 years and we now offer beef, pork, venison and lamb to customers all over New Zealand as well as exporting to seven countries by air and sea freight,” Nick says.

Green Meadows buys live cattle for processing from other farmers in the region and sources processed meat from other companies to supply its growing export business.

“It’s easy to sell our primal cuts but you have to find markets for your trim and the non-sexy cuts too.” – Nick Carey, Green Meadows Beef

Nick says having their own value-adding facility and retail outlet allows them to capture more of the efficiencies of processing meat at scale and generate better profit margins too.

Livestock are still processed through a contract abattoir, but the added value is captured in their own facility.

A big area of focus for Nick is looking for ways to extract a profit from the lowest-value cuts in each carcase. “It’s easy to sell our primal cuts but you have to find markets for your trim and the non-sexy cuts too.”

Close to 90% of the meat sold under Green Meadows in the domestic market goes outside the Taranaki region, either direct to consumers or to restaurants and food service customers.

About 40% of the total volume of meat sold under the Green Meadows brand is exported, and Nick says the balance is tipping more towards future growth from export markets.

“Our move into exporting was deliberate. We wanted to grow volumes, diversify our markets and also spread our margin risk.”

Taranaki couple launch online sales after retail & restaurant success

Another couple determined to succeed with their own meat brand are Taranaki farmers Shane and Kylie McDonald, who launched Meat To You in early 2023 to deliver beef direct to consumers across New Zealand through an online shop.

Their initial motivation for adding their own retail website was to showcase their Dexter and Simmental beef as a fully traceable product which is locally grown and processed in a low-stress system to enhance its eating quality.

Demand from online consumers and restaurants as far away as Wellington has grown and they now collect animals in their own stock truck from other suppliers for processing in their slaughter and processing facility at the farm.

Just over a year ago the couple opened their own café-restaurant called Farm to Fork, a few minutes’ drive from New Plymouth and their farm. It allowed them to move their retail outlet from the farm to the café where they could display their wide range of steak and processed products and serve café-style meals directly to the public each day.

The Bell Block venue is now licensed and opens three nights a week for a more restaurant-type experience where diners can pick their own choice of steak or choose one of the meat platters and compare the eating experience of a variety of meat cuts.

In early March, the McDonalds also launched a new website called Taranaki Prime where customers can purchase beef, lamb, pork and venison products, all sourced from farms across the Taranaki region and processed through the processing facility at their farm.

Shane says finding ways to deal with the whole carcase is one of the biggest challenges they face. They’ve chosen to increase the volume of beef they handle to generate efficiencies of scale in their further processing business.

They are also experimenting with a range of skincare products under their Leaf brand, made from the fat that surrounds the internal organs of a beef animal, and recently began developing their own pet food range marketed under their Noble brand, made exclusively from meat and internal organs without the fillers or additives common in many other brands.