Farming the Individual Cow, Not the Herd

A Taranaki farmer has embraced all of MSD Animal Health’s SenseHub Dairy Technologies to allow his high-producing cows to continue being milked beyond a typical dry-off date based on accurate, real-time information from wearables, sensors and drafting tools. Words Sarah Perriam-Lampp, Photos Brad Hanson.

Taranaki farmer Ed Whiting is redefining what it means farm to individual cows needs rather than to the herd’s needs using technology to simplify, not complicate, his farm’s workflows. He draws on experience in poultry, building a dairy farming system that is in operation most of the year by calving in summer, autumn, and spring, and MSD Animal Health’s SenseHub Dairy monitoring technology ecosystem sits at the core.

Taranaki farmer Ed Whiting is redefining what it means farm to individual cows needs rather than to the herd’s needs using technology to simplify, not complicate, his farm’s workflows. He draws on experience in poultry, building a dairy farming system that is in operation most of the year by calving in summer, autumn, and spring, and MSD Animal Health’s SenseHub Dairy monitoring technology ecosystem sits at the core.

“If you understand how to use the data it can be central to every decision on farm,” explains Ed. “We get far greater insight into an animal’s individual needs immediately.”

Decisions in real time

Ed’s shift towards high-tech farming began more than a decade ago, triggered by a simple decision to eliminate waste. “The kids were using reams of paper on the printer, and I threw it out on the lawn – not in anger, just as a figurative line in the sand,” he recalls. “We were going digital.” That moment led to implementing a fully paperless operation where all management records are digitised, traceable, and easily accessible.

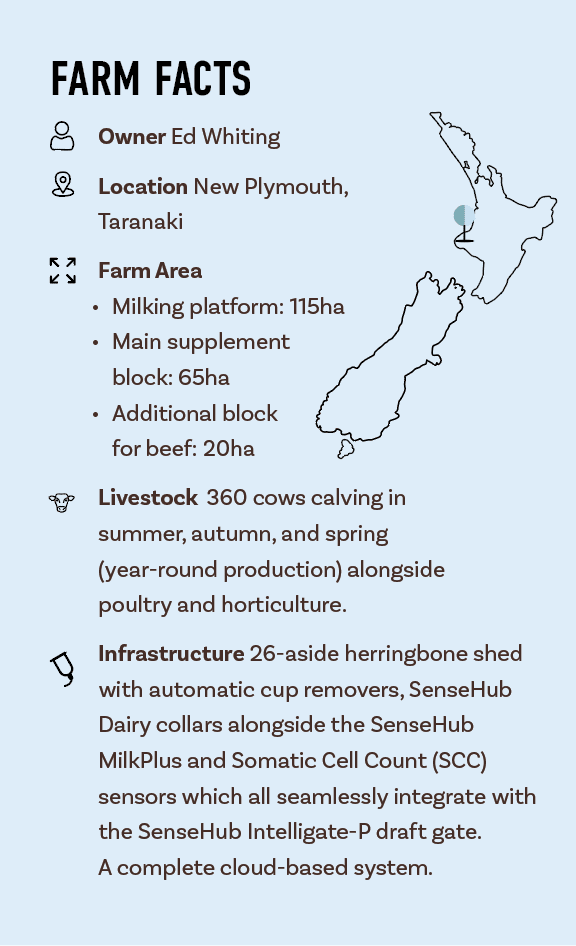

Today, Airport Farm runs a 115ha milking platform supported by 65ha across the drystock block and a smaller beef block. His 360-cow herd calves in summer, autumn, and spring, keeping the team busy with artificial breeding (AB) for eight months of the year.

“It’s a one-person shed now with the automatic cup removers and the automatic drafting gate,” Ed says. “Auto cup removers and the draft gate make milking painless and stress-free.”

The farm’s older 26-aside herringbone shed has been modernised with a Waikato milking plant upgrade, auto cup removers, and a SenseHub Intelligate-P draft gate, which has been in place for nearly six years.

The most recent upgrade is the addition of SenseHub Dairy MilkPlus and Somatic Cell Count (SCC) sensors. These were retrofitted into Ed’s shed between milkings, necessary because the farm operates year-round.

“It’s only been about a month, but already the data is impressive.”

The SenseHub Dairy milk sensors provide Ed with real-time measurements for yield, fat, protein, and SCC for every cow at every milking.

“You’re getting far greater insight into animal trends compared to one or two herd tests a year,” Ed explains. Then combined with rumination and heat detection data from SenseHub Dairy collars, he now has a detailed, individual-level view of his herd.

For Ed, the real benefit is not the technology itself, but the decisions it enables. “Anything digital is traceable,” he says. “It’s not about saving money, it’s about making the job easier for everyone.”

The system has also changed the daily routine for his staff. Cows are identified automatically at the shed entrance, which structures the milking process without rushing.

“Instead of following a set calendar we dry the cows off based on their condition. High-producing cows can then continue to be milked through winter, improving productivity and animal health.”

By monitoring trends in production and health, Ed can intervene earlier when problems arise, whether that means adjusting feed, managing mastitis risk, or improving reproduction outcomes.

He expresses his praise for SenseHub Dairy for health and heat detection. “SenseHub Dairy, most of the time, is better than a human! We rely on it heavily.”

Advice for farmers

Ed sees adopting advanced technology as inevitable for competitive dairy farming. “You’ve got to bite the bullet at some stage,” he says. “You have just got to get on with it. Technology doesn’t replace good farming; it enhances it.”

The key, he explains, is using the tools to improve decision-making and reduce stress on both people and animals. By leveraging data from SenseHub Dairy alongside other systems, he has built a model where every cow receives the right level of attention, every decision is evidence-based, and every member of the team can work more efficiently.

The farm now operates with fewer manual tasks, more precise decision-making, and a higher standard of care for both cows and people. It’s a model built for resilience in an industry facing labour shortages, environmental pressures, and market volatility.

Ed’s learnings

- To maximise value make sure the technologies integrate where possible by linking milking data, health metrics, and reproductive records into one platform.

- Focus on usability for your team as it should make yours and their job easier, not more complicated.

- Adopt gradually if needed. Ed’s system has evolved over years, starting with smaller changes like auto cup removers before adding more advanced sensors.

- Use data for action, not just reporting. The benefit comes from responding to trends, not simply recording them.