A playbook of passion & profit for future beef

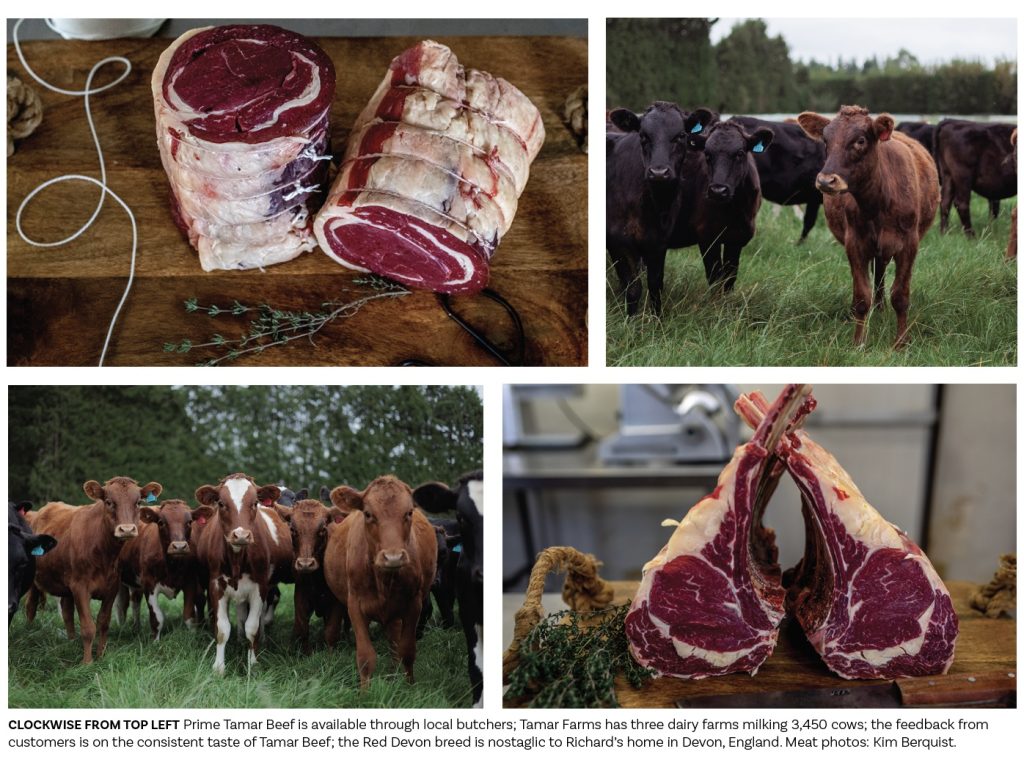

The rewards of a minimal bobby calf policy for the Wrights’ dairy farms paired with a nostalgic love of Red Devons has seen the growth of Tamar Beef rearing beef-cross calves to marbled steak direct to the consumer. Words Sarah Perriam-Lampp, Photos Ben Doubleday.

If there is a new way to farm profitably that is environmentally and socially conscious, you can bet Richard and Chrissie Wright have not only thought about it, they were the first out the gate on a new concept before the concept was even a story in the media.

The Mid-Canterbury entrepreneurial farming couple from Tamar Farm in Mount Somers have their fingers in so many pies they have their own pies – literally. The motivation for their progressive farm-to-table agribusiness is a passionate playbook on how to farm the very best quality products direct to their customer with their Tamar Beef. And one thing it’s never been is easy.

“It all started with the pipe dream of owning a restaurant, so we bought the Slip Inn in Havelock,” explains Chrissie, 450km north of their farm, but on the shores of their beloved holiday spot, Pelorus Sound. “It was a little bit of a mid-life crisis but it was what kicked off Tamar Beef.”

The restaurant, for all its flaws, sparked the idea to market their own Red Devon cross meat direct to diners when they realised what quality the chefs were buying from the wholesalers. And then came the realisation of the lack of demand for the lower-value cuts that led to a coffee cart with Tamar pies and sausage rolls on the slipway for all of the boaties en route to their baches.

RED DEVONS – THE SELF-CONTAINED DAIRY BEEF MODEL

Scale has never been an issue to launch their meat brand – the Wrights farm a total of 2,000ha with three dairy units milking 3,450 cows as well as a drystock block and a 160ha cropping block finishing lambs.

Richard has had a laser focus for over a decade to build a self-contained farming business model starting with wintering all dairy cows and replacements on farm as well as winter-milking 300 cows.

The home block is the 846ha drystock block which grazes all the dairy replacements for the dairy farms as well as rears and finishes bulls and beef heifers. This is also home to an autumn-calving breeding beef herd of 365 Red Devon cows, a passion for the farmer originally from Devon in England.

This allows the Wrights to have a minimal bobby calf policy. They do a 10-week mating including sexed semen, short gestation dairy genetics and Red Devon semen from the best on-farm bulls to rear beef-cross calves.

“Chrissie loves rearing the calves,” says Richard. “Between the family we do over 1,000 beef-cross calves every year calved in the spring with the beef-cross heifers raised for prime for our Tamar Beef, and the balance of bulls finished or retained for breeding.” The Devon beef cows calved in the autumn helps spread the workload on the farm throughout the year and helps with prime trade demand.

Tamar Farm has some of the rare Red Devon genetics in New Zealand sourcing their gene pool solely through imported straws with a recent strong bloodline from Tillybrook Ruby in the UK. The traditional horned breed is renowned for their easy calving, early maturing and docile temperament.

“While other breeds were chasing lean beef in the eighties and nineties, the Red Devons never changed from their traditional muscle and fat composition that produces well-marbled, tender and succulent beef,” explains Richard.

“The report says that the number of days to finish is a key driver of GHG emission intensity.” – Fonterra and Nestlé funded GHG Report on Tamar Beef

The selection process in the Red Devons is rigorous, with three mobs from the elite genetics through to breeding for service bulls. They use Mat Bailey from Bailey Scanning for their IMF and EMA, carcase scanning all of the Red Devons with the latest CUP Lab technology from the US that allows carcase data analysis with improved accuracy of raw scan results at 95–98%.

Richard says that the noticeable difference in their meat always lies with the consumers. They have the animals processed at around a 260kg carcase and then sold to butchers for processing for their prime cuts and mince for their pies. Sims Bakery who make the Tamar Beef pies has recently switched to sourcing mince from Tamar for their own pie brand.

“Tamar Farm Red Devon beef is perfect, lightly marbled meat that is juicy and tender,” says Mike Hanson, owner of Netherby Meats, Ashburton. “This is a reflection of Tamar Farm’s farming practices, caring for their grass-fed animals and keeping them in a happy, stress-free environment. That is what our customers love – they enjoy knowing where their beef is raised and that it’s treated with the knowledge and passion Richard and Chrissie Wright have for their animals.”

Christchurch’s renowned steak restaurant, Bessie, proudly serves Tamar Beef on their menu. The Wrights are also working with Nuro, a grass-fed tallow that shows Red Devon is high in omega-3.

VIRTUAL FENCING ON BEEF COWS

The Mid-Canterbury farm is flush with feed after an unusually wet summer with knee-high mixed swards with plantain and chicory. And in the middle of the dense pasture in the large paddock is a mob of cows with Halter collars standing in their patch behind their invisible fence. As the tech-savvy farmer, Richard hounded Craig Piggott at Halter to have a go at beef when he wasn’t that interested at the time. He was even looking to import wearable technology from Norway until Craig folded and used Tamar as a test farm for rolling out Halter on beef cattle.

LIFTING UP THE NEXT GENERATION

LIFTING UP THE NEXT GENERATION

The Wrights believe the best way to achieve their farming goals is to be a progressive farming system utilising new technology, efficient and best farming practices, and having a high production system at a low cost so it gives them financial options.

Richard and Chrissie are incredibly hard workers whose farm ownership journey was through sharemilking in the North Island and then an equity partnership in Ashburton. They are now lifting up the next generation of landowners through the same equity model that got them on the ladder.

The couple came to Mount Somers in 2002 just as three neighbours were looking to exit and so grew in size rapidly over the years, and they now have the passion to give back with valued sharemilking relationships. At the Strathclyde and Wightmans Dairies which cover 530ha, they sharemilk 2,000 cows – 50% with brothers Manoj Kumar and Sumit Kamboj who won the 2021 New Zealand Share Farmers of the Year. In 2025, they are taking over another Canterbury dairy farm to support the brothers to farm ownership. On their Te Mahanga farm of 370ha they are growing lower order sharemilkers Robin and Kirstie Hornblow in the same direction.

While daughter Jess and fiancé Tim are architects in London, the Wrights’ sons, Tom and Olly, are both farming in the area. Tom manages the agricultural machinery, irrigation and cropping as well as lamb finishing at Methven where he lives with partner Anna. Olly and Kate are growing their own business with a lease block on the neighbouring farm.

DEFINING EMISSIONS

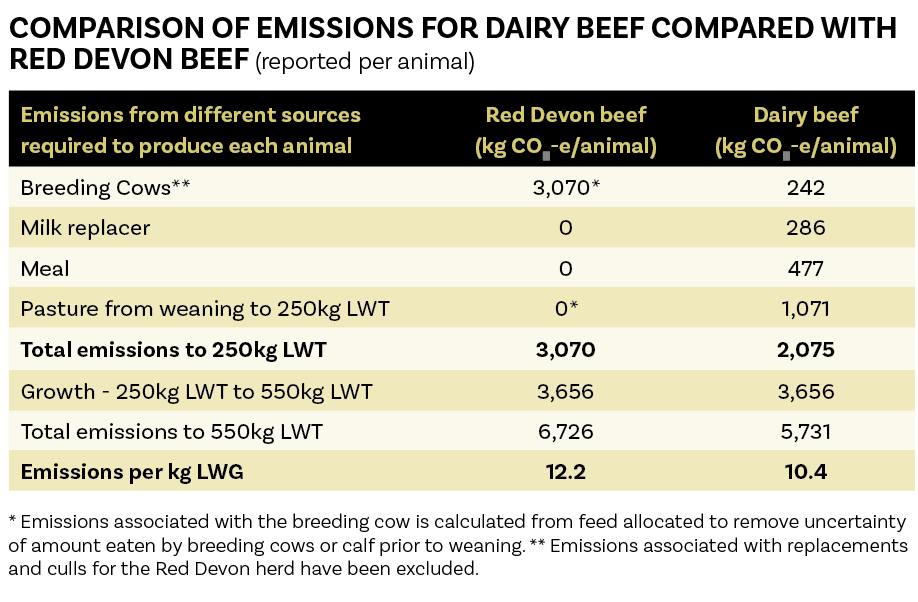

Fonterra and Nestlé have funded a project to quantify the GHG emissions for each product type produced by Tamar Farm in the 2023–24 season and from these calculations identify opportunities for reductions in GHG emission intensity.

Fonterra has a target of a 30% reduction in GHG emission intensity from the products they supply to customers from 2030, and of this target, 7% is expected to come from reductions in on-farm emissions. These reduction targets include emissions associated with the dairy support function of the dairy platform. There is a wide variety of dairy support systems that are often integrated with other enterprises, which makes measuring and reducing emissions associated with the dairy support function difficult.

The Tamar business is an example for these opportunities but also highlights the complexity of the farm business which makes calculating emissions and improvement opportunities difficult to isolate relative to each product type.

Emissions associated with beef production depend on how the beef animals are sourced, and the number of days to finish. Dairy beef is associated with 15% lower emissions than the Red Devon beef due to reductions in emissions associated with getting the animals to 250kg liveweight (weaning liveweight target for the Red Devon herds).

The report says that the number of days to finish is a key driver of GHG emission intensity. This is associated with the maintenance requirement across the growth of the beef animal and improved feed conversion efficiency at higher growth rates. It states that reducing the number of days to finishing while finishing animals to the same weight will reduce emissions intensity of beef production.

Management decisions on the beef/support blocks prioritise feed to some stock classes over others through the season. Some stock classes have a ‘clean-up’ function that reduces their efficiency and enhances efficiencies across the whole operation. These decisions tend to benefit dairy youngstock as the highest-priority animals. These less-tangible aspects should be considered when looking for future opportunities to improve.

THE FUTURE OF TAMAR BEEF

The biggest lesson the couple have had is to control your whole value chain. They have tried it all – from selling to butchers and losing their story along the way, to getting into bed with wholesalers who promise the earth but want it for schedule price, as well as being sold the dream by chefs who are only after primal cuts.

“Tamar Beef for us hasn’t been solidly about making lots of money, it’s the joy that every farmer wants to see their hard work enjoyed by customers who know where their meat comes from,” says Richard. “We are still tinkering to get the distribution model right and we are always investigating options on how we can bring key talent into our business with an equity stake – like a young butcher – to grow the business.”

Chrissie says Richard would have an on-farm micro abattoir selling subscription boxes tomorrow if he could. And after half a day with them both, they probably will, as everything the Wrights set their mind to happens.